The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Enhancing Efficiency: The Advantages of Multi-Head Weighers in Speed and Accuracy

09/27/2023

nVenia’s OHLSON Brand Multi-Head Weighers have become the industry standard for weighing applications across a multitude of industries. For those embarking on their initial packaging automation venture or considering a semi-automatic packaging system, understanding the concept of multi-head weighers is crucial.

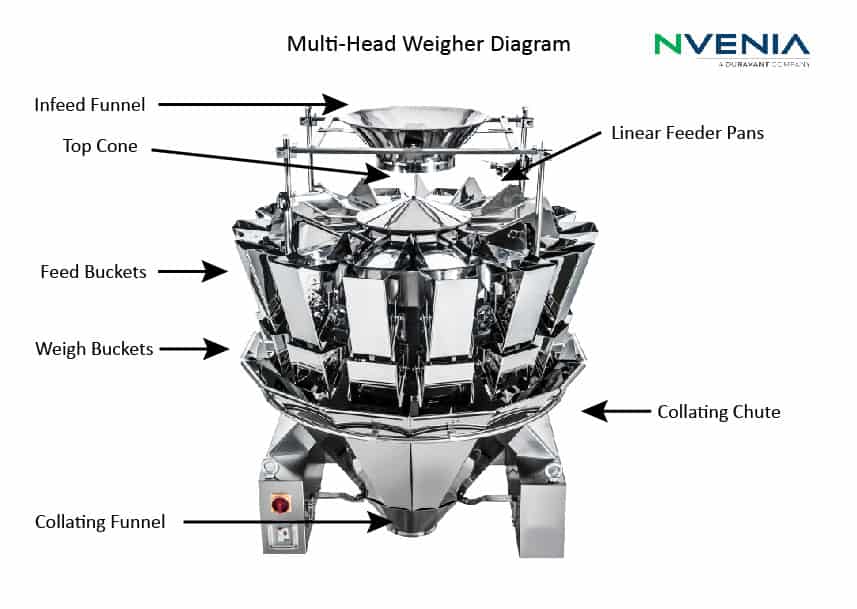

In essence, a multi-head weigher serves the purpose of dividing bulk products into smaller, pre-defined increments based on the programmed weights within its software. The process begins with the bulk product being dropped into the scale through the infeed funnel situated at the top. This is generally accomplished using an incline conveyor or a bucket elevator.

Multi-Head Weighers function by the top cone and feed pans vibrating, creating a gentle outward movement of the product from the center of the machine towards the buckets positioned around the scale’s edge. To suit different products and fill weights, the system offers various options and software settings that can be adjusted accordingly.

In certain applications, the scale is equipped with dimpled contact surfaces, which minimize the surface area for sticky products like gummies to stick to. Additionally, the bucket sizes differ based on the specific product and desired fill amount. Generally, bulkier products or larger containers necessitate larger buckets, while the opposite holds true for smaller items.

Each weigh bucket is equipped with its own load cell, continuously measuring the quantity of product it contains while simultaneously receiving a continuous supply of product.

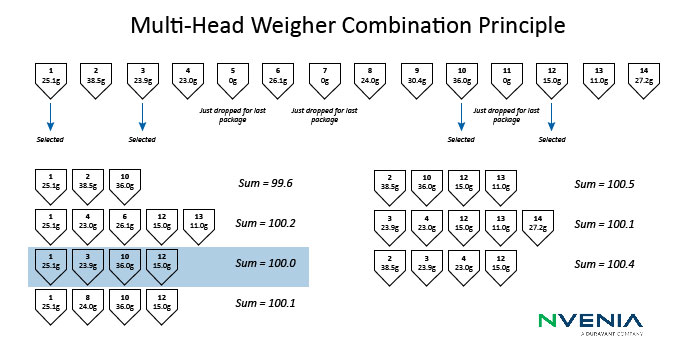

To reach the target weight, the scale's software selects a combination of buckets that collectively add up to the required amount. For example, if the target weight is 100 grams, the system evaluates all 14 weigh buckets and decides to release buckets 1, 3, 10, and 12 to reach the desired weight threshold. Within a fraction of a second, it reassesses all the buckets and selects the subsequent combination to reach the desired weight, ensuring an accurate and efficient weighing process.

Combination weighers offer two primary advantages: speed and accuracy.

An nVenia, OHLSON Brand multi-head weigher boasts highly precise load cells, capable of achieving accuracies down to fractions of a gram. By incorporating additional check weighing features and modifications, the already impressive accuracy range can be further refined.

Unlike linear scales, multi-head weighers are not susceptible to the challenge of weighing clumps, ensuring consistent and exact measurements.

OHLSON Brand Multi-Head Weighers are also known for their exceptional speed. With each head continuously replenishing and weighing the product, the multi-head weigher significantly outperforms a manual scale operated by an individual.

Under nVenia's OHLSON Brand, standard multi-head weigher models range from 10 to 24 heads. The larger the number of weighing heads, the more combinations the computer can generate, resulting in improved accuracy and higher operational speeds.

Are you in need of multi-head weighing solutions? Request a quote from us, and we will assist you in finding the ideal weigher tailored to your product's requirements!