The Duravant family of operating companies serve the food processing, packaging and material handling segments.

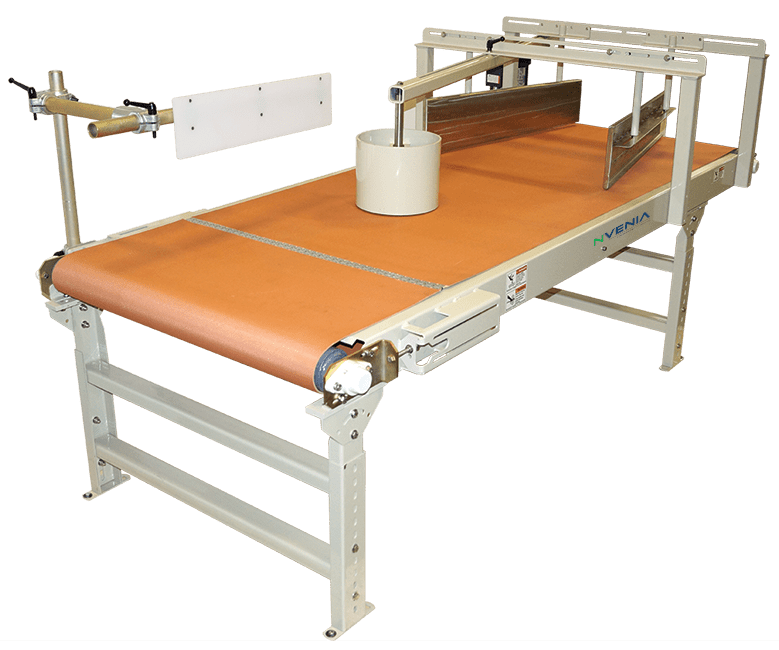

Hamer Brand Model 2090 Form Fill and Seal (FFS) Bagging Machine

Our Hamer Model 2090 Form, Fill & Seal Bagging Machine is the most capable and flexible industrial Form, Fill & Seal packaging system available. Extensive customer-focused design actions have improved machine uptime and reduced annual maintenance costs by almost sixty percent. Its high speed, straightforward operation and simple maintenance make the Hamer Model 2090 the industry’s first choice for reliable bagging automation.

The Hamer Model 2090 features a sturdy 4″ structural steel frame, powder coated to withstand corrosive environments. The hot air sealer features an automatic pneumatic separator control that separates the two sides when a bag is not present – reducing wear on the sealer belt, bearing, and pulley. All operational components are top-mounted for simplicity and all adjustment controls are scaled for simple, trouble-free bag size changes. A pneumatically actuated bag perforator provides up to twelve vertical holes along the edge of the bag to facilitate air removal for effective bag palletizing. The perforators are mounted to the hot knife assembly, improving performance and reducing wear, and Teflon knife backing keeps bag seams clean.

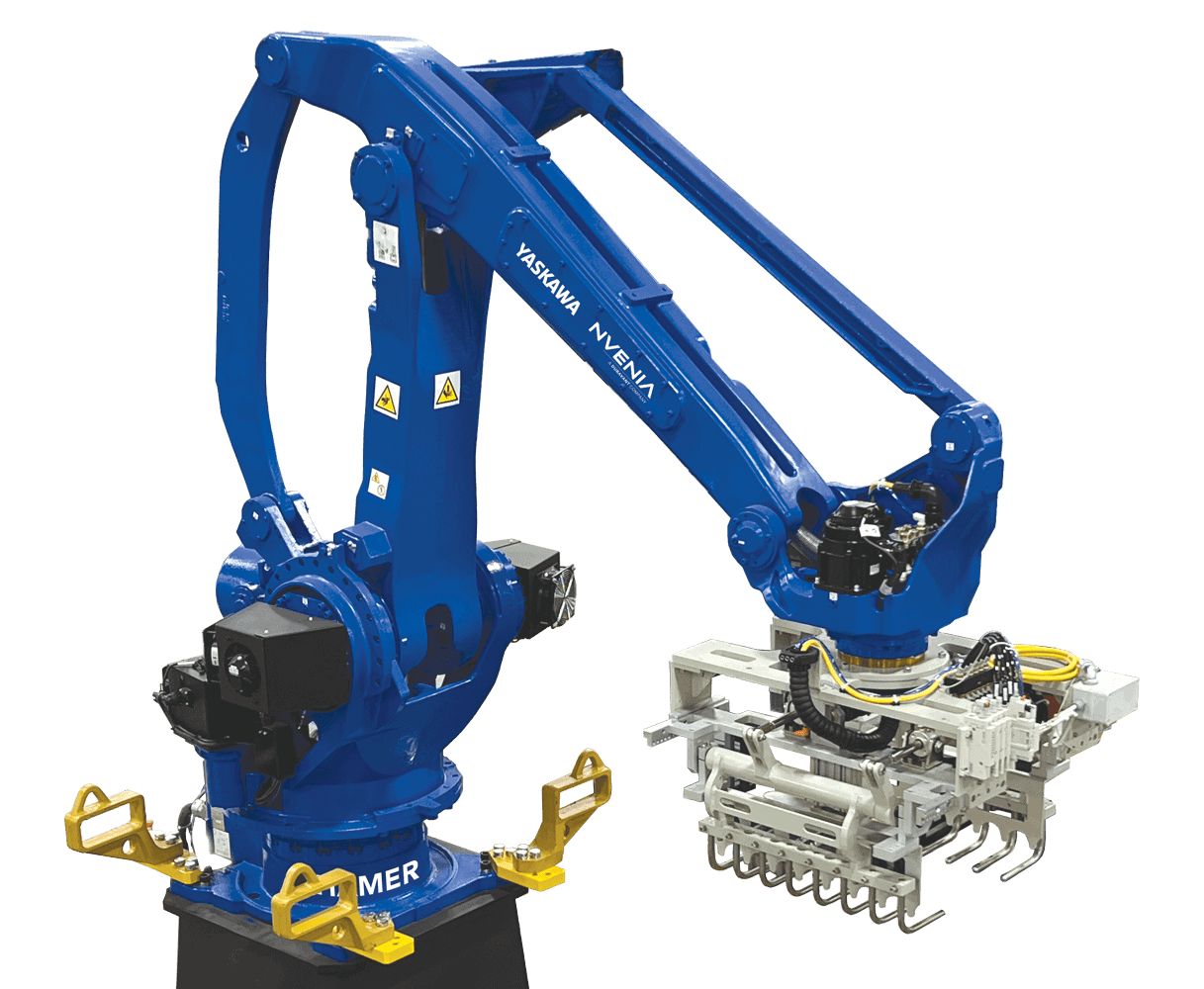

Hot Knife Bag Top Trimmer Accessory

Adjustable Blade Carriage: Full use of the blade edge before changeout

Easy Blade Replacement: Quick and simple worn blade change

Vacuum Blower: Efficient film scrap removal (optional scrap collection)

Are you interested in this product?

We are here to help.

Features

- 24 VDC Solid State Controls

- UL listed NEMA 12 control panel

- Simplified operator touch panel

- Heavy-duty powder coated 4 in structural steel frame

- 304 stainless steel product contact points

- Zinc dichromate plated internal components

- Wire mesh safety enclosure with door interlocks

- MaxFill chute provides maximum product volume and faster filling

- Bag counting, operational alarms, and diagnostics

- Handheld remote operator control

- Five color spectrum photo eye with learn feature

- Vertical roll holder with pneumatic core chuck

- Top frame-mounted internal components

- Automatic bag top heat sealer with auto-open

- QuikAdjustTM chute adjustment for fast bag size change

- Heavy-duty hardened self-cleaning dual sealed pulleys

- Variable speed AC motors on heat sealer

- Double heat seal top seal with knurl for seal integrity

- Extended length bag top seal cooling plenum

Standard Specs

Standard Specs

Machine Dimensions

5′ 7″ H x 4′ W x 21′ L

Speed

Up to 34 BPM

Film Types

- Bag Size: Width: 10 3/4″ to 26″, Length: up to 42 in

- Bag Thickness: 2 mil to 8 mil low density polyethylene

Polyethylene Film Stock Specifications:

- Film type: C-fold rollstock

- Material thickness: 2 mil to 8 mil

- Core diameter: 3″ on 24″ O.D. vertical roll

- Roll diameter: 24″ vertical or up to 48″ horizontal

- Optional gusset: 3″ to 6″, 4 mil max

Electrical Requirements

230 VAC, 3 Ph, 60 Hz, 60 A Standard

Other power options available

Air Requirements

45 CFM @ 80 PSI

Accessories

Accessories

OPTIONS:

- Hot Knife Bag Top Trimmer

- Multiple product infeed and transition chutes with MaxFill(TM) for faster bag filling

- Hardox (R) 1/8″ steel chutes and transitions also available

- Transition chute shaker

- Additional fill opening assembly (additional chutes sold separately)

- Quikadjust(TM) tool-free high speed bag change – eliminates need to remove pulleys

- JamControl(TM) bag jam sensor for overfilled bag detection and removal

- Bag top seal air scrubber for dust removal

- Bag top trimmer with film scrap removal (additional air required)

- Horizontal hole punch for air relief

- Vertical film lift device

- Second vertical roll holder

- EZ Load II(TM) horizontal roll holder

- Power film lift with powder coated frame, operator control panel, and splice assist

- Horizontal film roll stock holder with powder coated frame and powered film pull

- Horizontal film roll stock holder with mounting and controls for Bellmark Printer (printer not included)

- Motor starter/VFD front panel resets

- Grace port 3 PH indicator

- Allen Bradley Compactlogix PLC upgrade

- Multiple power options (208V, 460V, 540V @ 60 Hz and 230V at 50 Hz)

- NEMA 4X stainless steel transformer for 460V, 3Ph, 60 Hz (Contact your rep for other voltages)

- NEMA 4X corrosion resistant control panel with junction boxes in 304 stainless steel

- FFS corrosion protection package in 304 stainless and painted conveyor beds and heat sealer

- 316 stainless steel product contact points

- Mitered corner sealer (45 degree bag corners)

- Bottom gusset reformer (3″ to 6″)

- Remote communications: Ethernet, Web Based, Modem

- Bag Handles: Handle punch, Patch handle, heather/patch handle

- Easy-open bag perforator

- Bag coder (4 or 8 character options)

- Inkjet printer

- Thermal transfer printers in multiple sizes

- Increment/counter – allows use of non-eye mark films

- Frame extension with guarding for optional feature protection (adds approx. 34″ to machine length)

- Machine enclosure/doors Lexan upgrade – replaces wire mesh

- Industrial locking casters for portability

- Steel wheel kit for rail mounting