The Duravant family of operating companies serve the food processing, packaging and material handling segments.

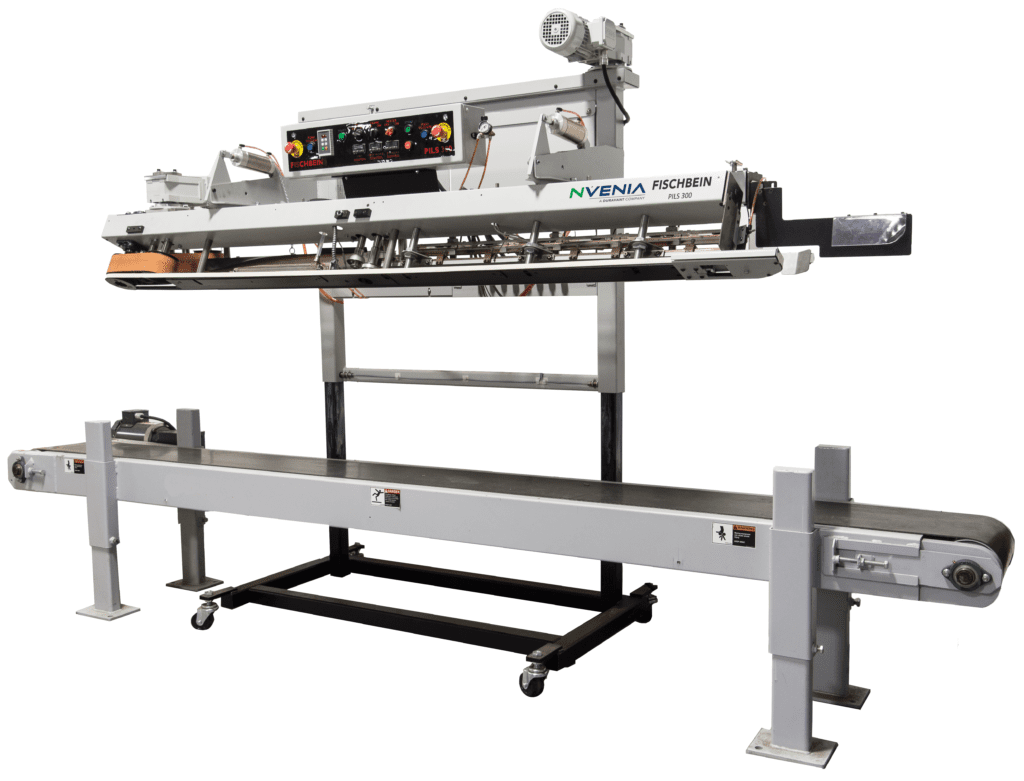

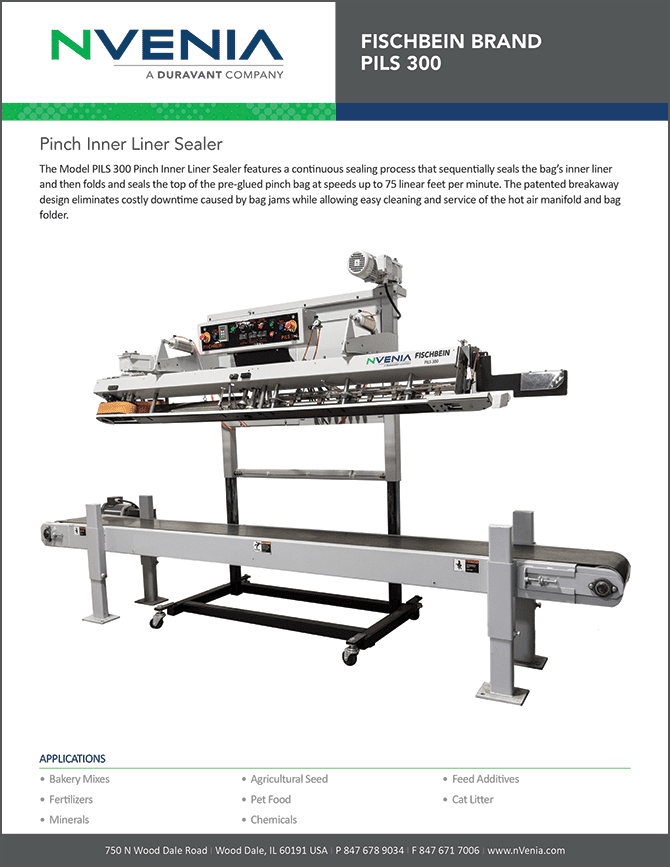

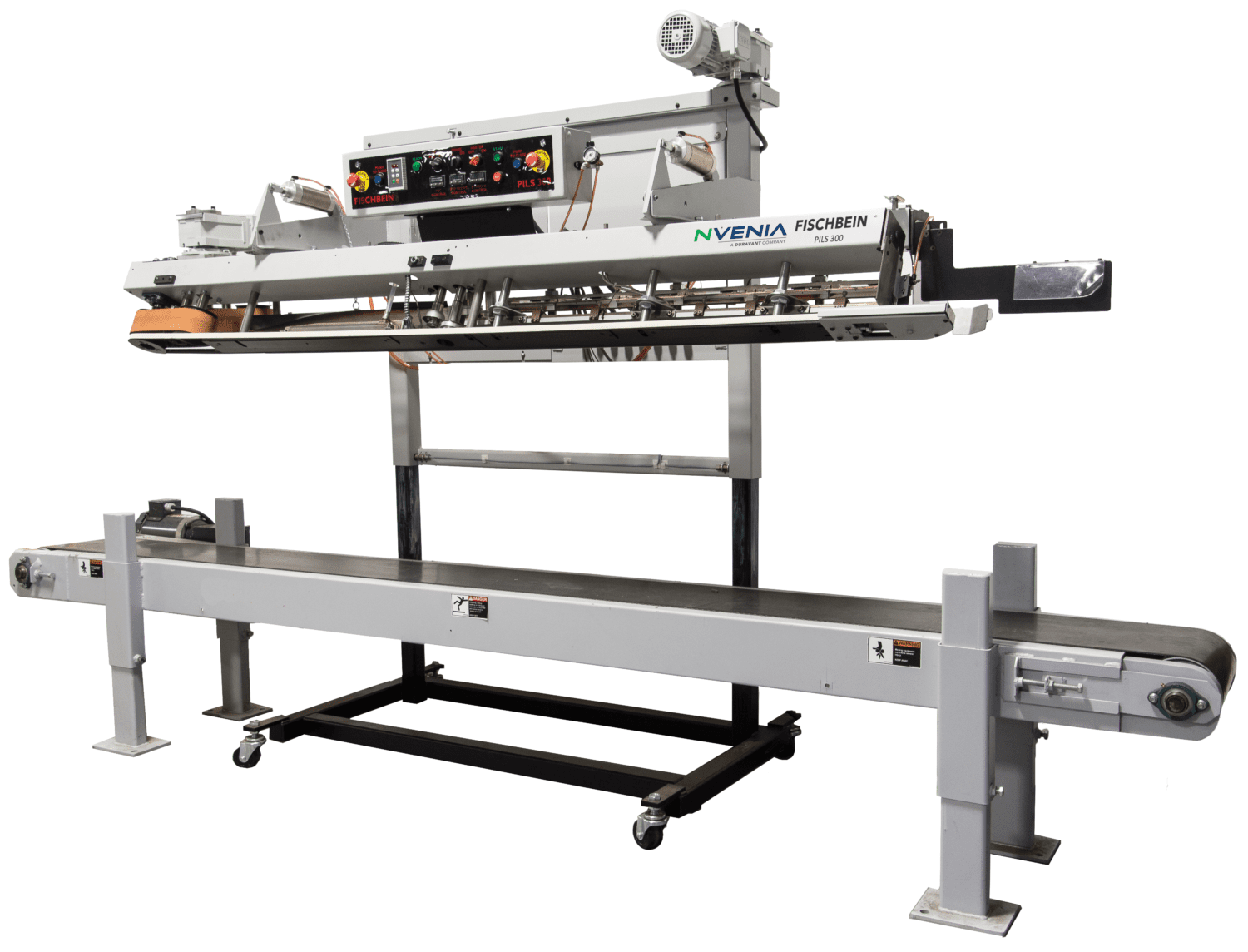

Fischbein Brand Pinch Inner Liner Sealer – PILS 300

Our Fischbein Brand PILS 300 Pinch Inner Liner Sealer features a continuous sealing process that sequentially seals the bag’s inner liner and then folds and seals the top of the pre-glued pinch bag. Operating at speeds up to 75 linear feet per minute, the PILS 300 is safe and easy to use. It can be easily integrated in semi or fully automated bagging applications. The patented breakaway design eliminates costly downtime caused by bag jams while allowing easy cleaning and service of the hot air manifold and bag folder.

Are you interested in this product?

We are here to help.

Features

Standard

- Multi-wall paper, pinch bags that have a pre-applied hot-melt adhesive strip, and heat-sealable polyethylene or foil inner liners. Can also be used to seal standard pinch-style bags that do not have inner liners.

- Patented breakaway design for fast, easy service.

- Safe and easy to use control panel with digital temperature display, keypad for variable speed control, and dual emergency stop buttons.

- Over-temperature sensor auto shutdown.

- Motorized adjustable seal height to reduce change-over time.

- Bag top air scrubber removes product debris from seal area.

- Dust tight NEMA 12 rated electrics

Options

- Left to right operation

- Reverse fold – rear direction

- Extended infeed for automation applications

- Additional motor starter and contactor for conveyor

- CR Plus 2 part corrosion resistant powder coat finish

- Stainless steel NEMA 4 X washdown version

- 575 VAC

Bag Types

Multi-wall paper gusseted open mouth pinch bags with heat-sealable inner liner

Gussets

Any size including flat bags

Free Bag Top

Minimum 6 in (15.2 cm)

Standard Specs

Standard Specs

Dimensions

L 114 in (290 cm) x D 37 in (94 cm) x H 92 in (234 cm)

Speed

Up to 75 linear feet per minute

Electric

230/380/460V-3PH-60Hz, 24 VAC

Air

90 PSI, 12 SCFM