The Duravant family of operating companies serve the food processing, packaging and material handling segments.

RFM-1014 Pre-Made Pouch Rotary Bagging Machine

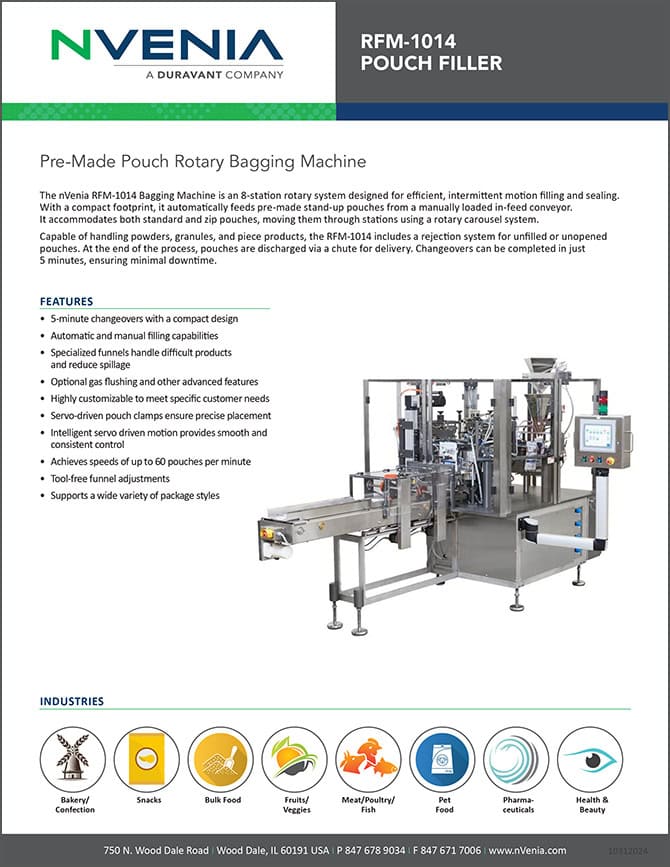

The nVenia RFM-1014 Bagging Machine is an 8-station rotary system designed for efficient, intermittent motion filling and sealing. With a compact footprint, it automatically feeds pre-made stand-up pouches from a manually loaded in-feed conveyor. It accommodates both standard and zip pouches, moving them through stations using a rotary carousel system.

Capable of handling powders, granules, and piece products, the RFM-1014 includes a rejection system for unfilled or unopened pouches. At the end of the process, pouches are discharged via a chute for delivery. Changeovers can be completed in just 5 minutes, ensuring minimal downtime.

Are you interested in this product?

We are here to help.

Features

• 5-minute changeovers with a compact design

• Automatic and manual filling capabilities

• Specialized funnels handle difficult products and reduce spillage

• Optional gas flushing and other advanced features

• Highly customizable to meet specific customer needs

• Servo-driven pouch clamps ensure precise placement

• Intelligent servo driven motion provides smooth and consistent control

• Achieves speeds of up to 60 pouches per minute

• Tool-free funnel adjustments

• Supports a wide variety of package styles

Specifications

Specifications

Station Configuration

1: Infeed conveyor / Conveyor air blast / Pick & Place / Pouch Clamp Opener

2: Pouch Opener / Pouch Open Air Blast 1

3: Pouch Open Air Blast 2 / Pouch Detection

4: Filling Funnel

5: Pouch Closing

6: Overfill Detection / Top Seal Station

8: Discharge Mechanism / Exit Chute

Optional Equipment Station Configuration

2: Data Coder / Gusset opener

3: Zipper Opener

4: Timing Hopper / Metal detector/ Settling / Agitator

5: Gas Flush / Pouch Duster / 2nd Fill station

7: Water Chiller / Top seal cooler

8: Discharge Station (Customer Discharge conveyor)/ Reject Chute