The Duravant family of operating companies serve the food processing, packaging and material handling segments.

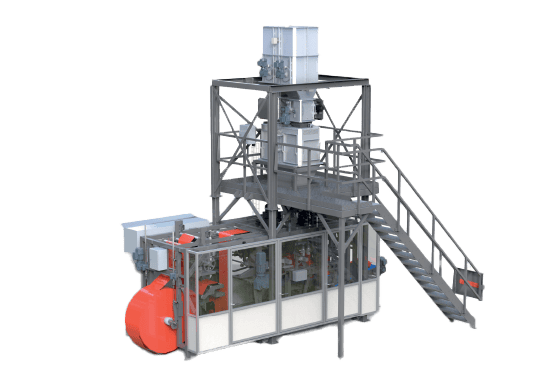

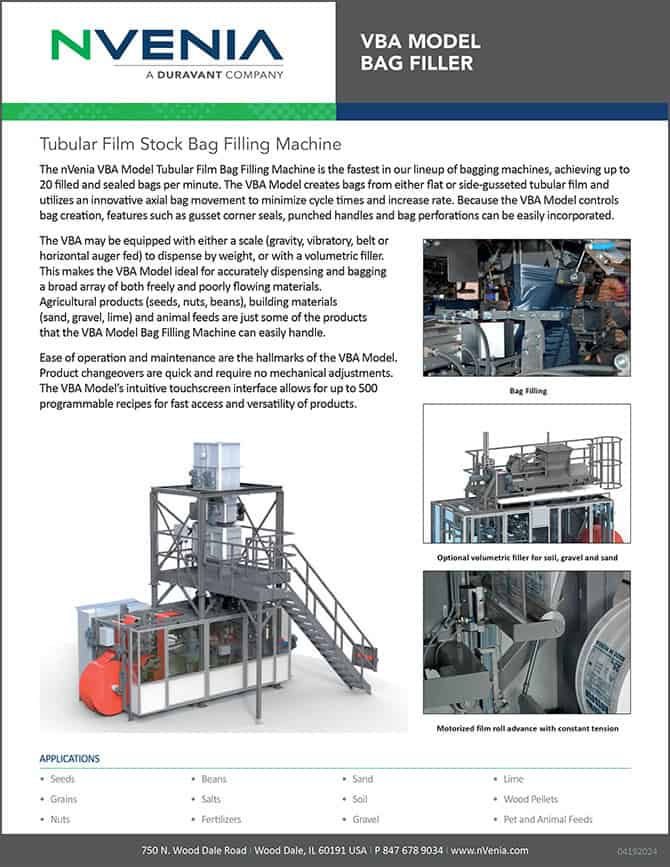

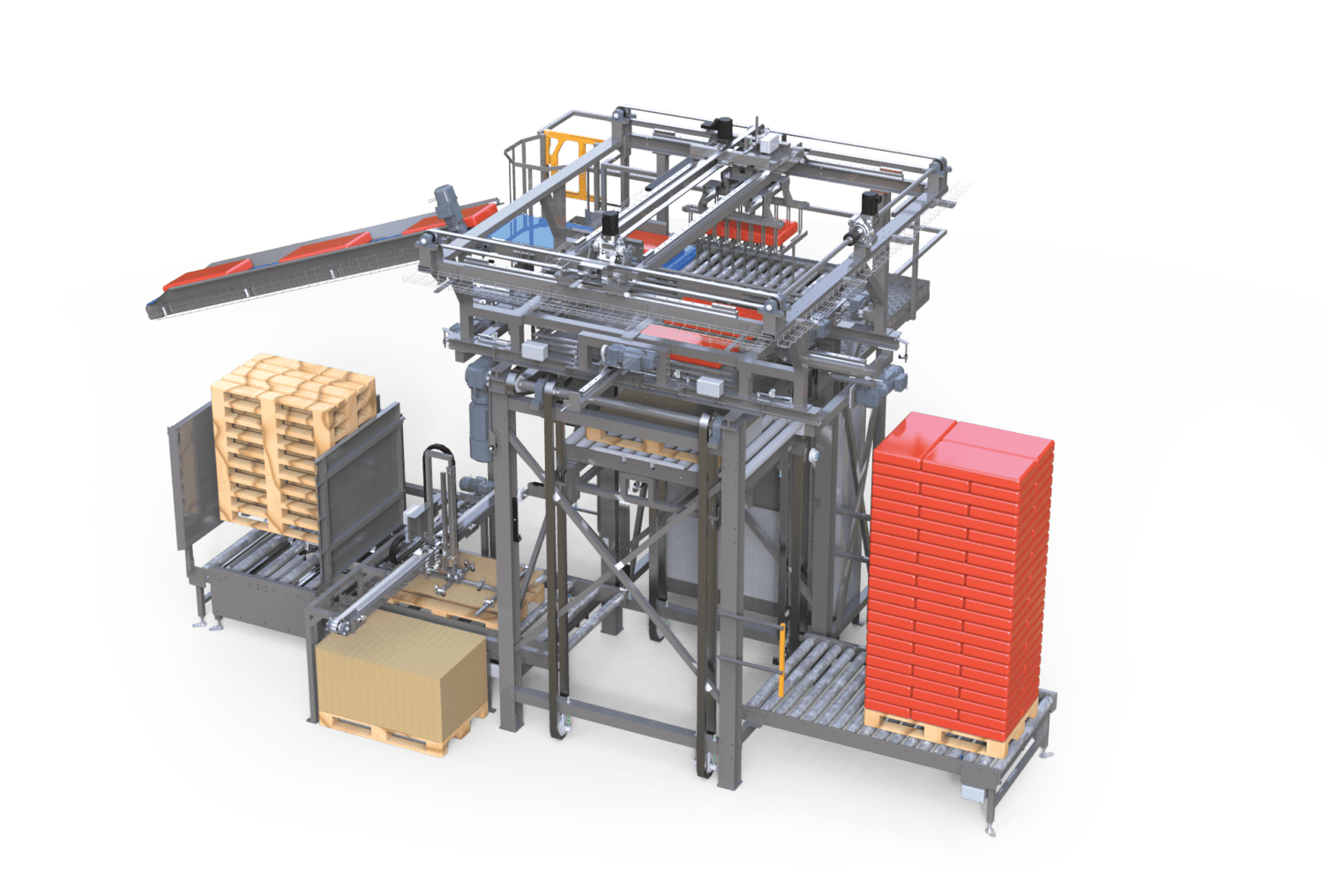

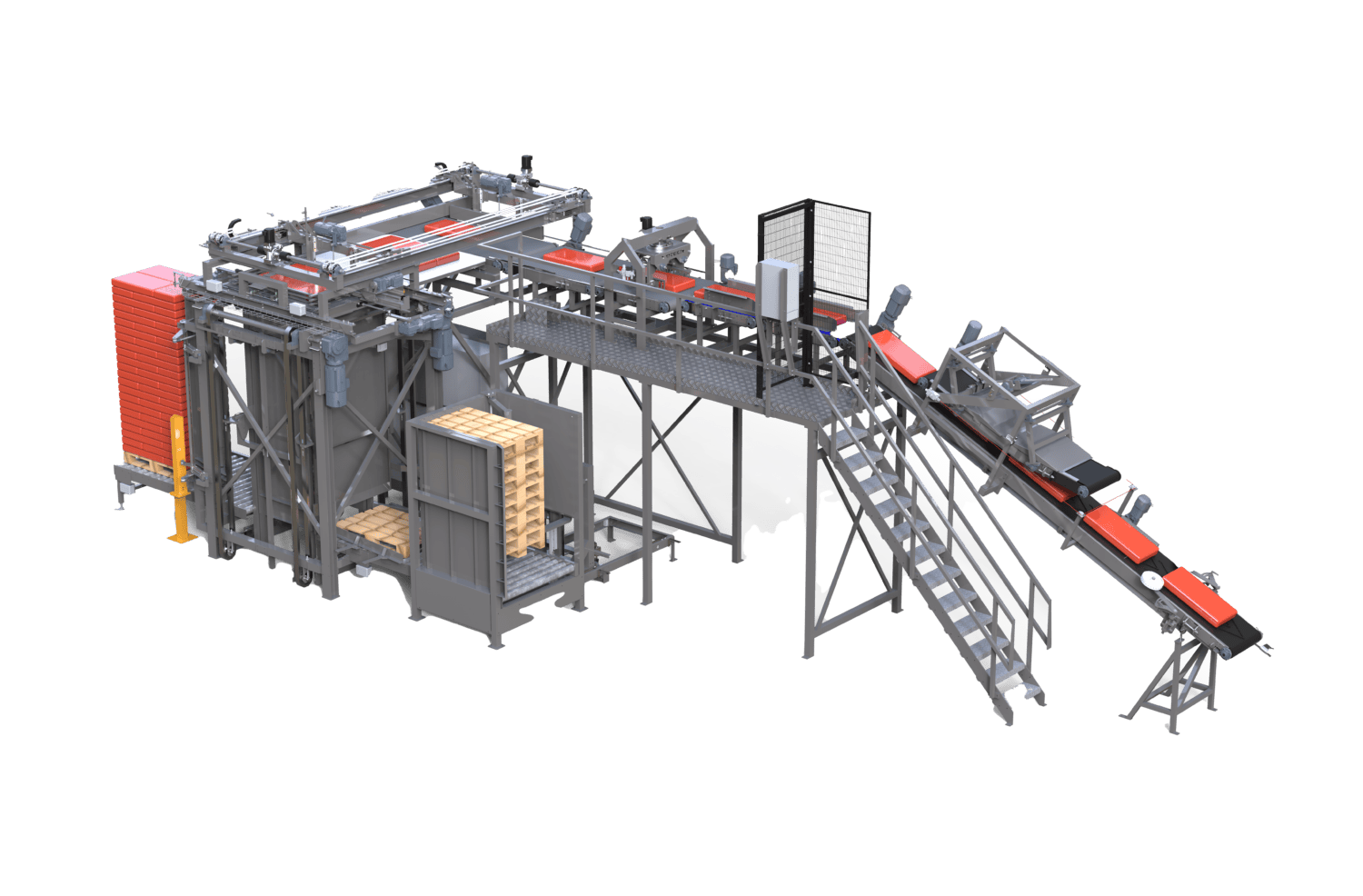

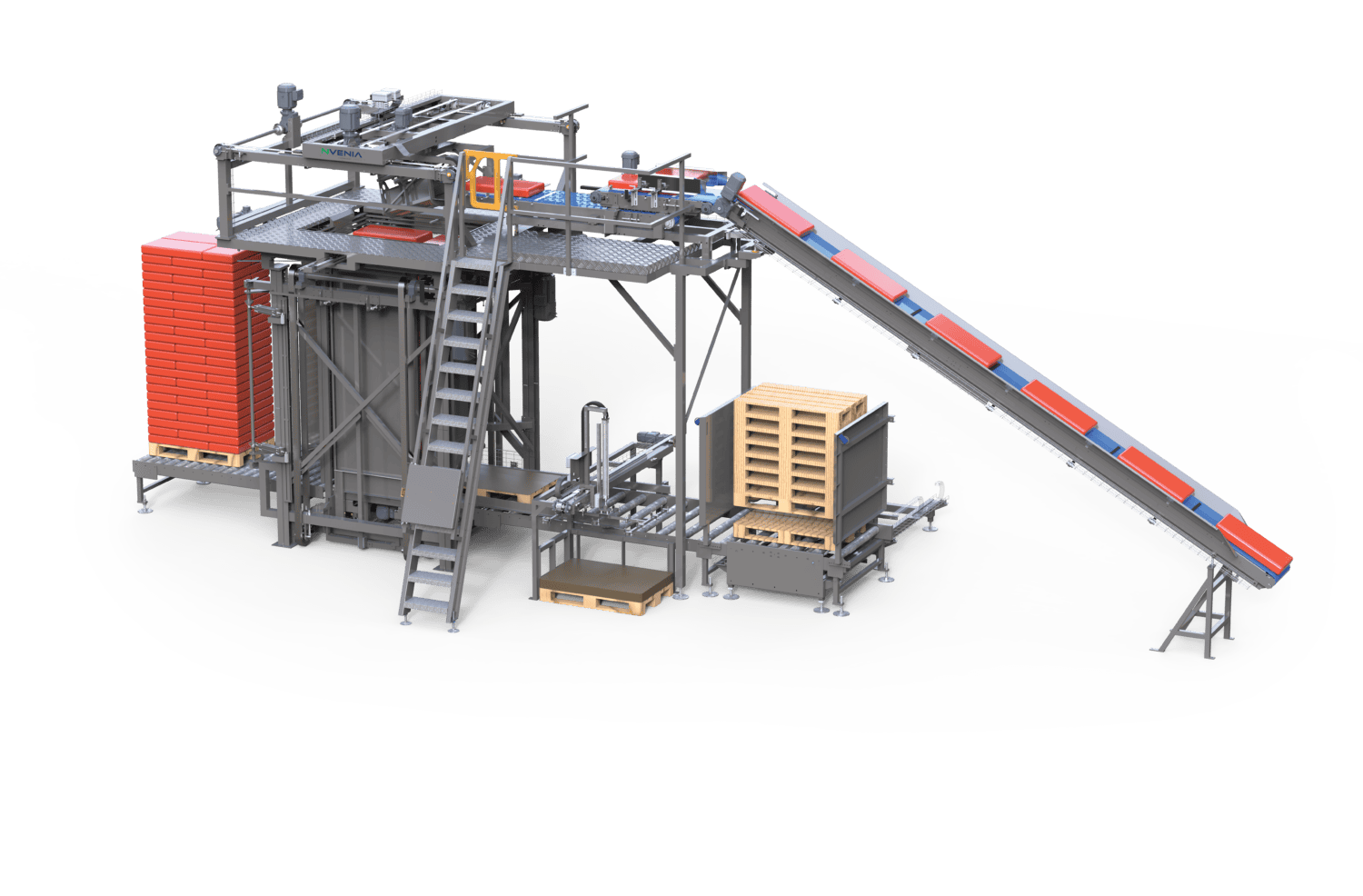

VBA Model Tubular Film Stock Bag Filling Machine

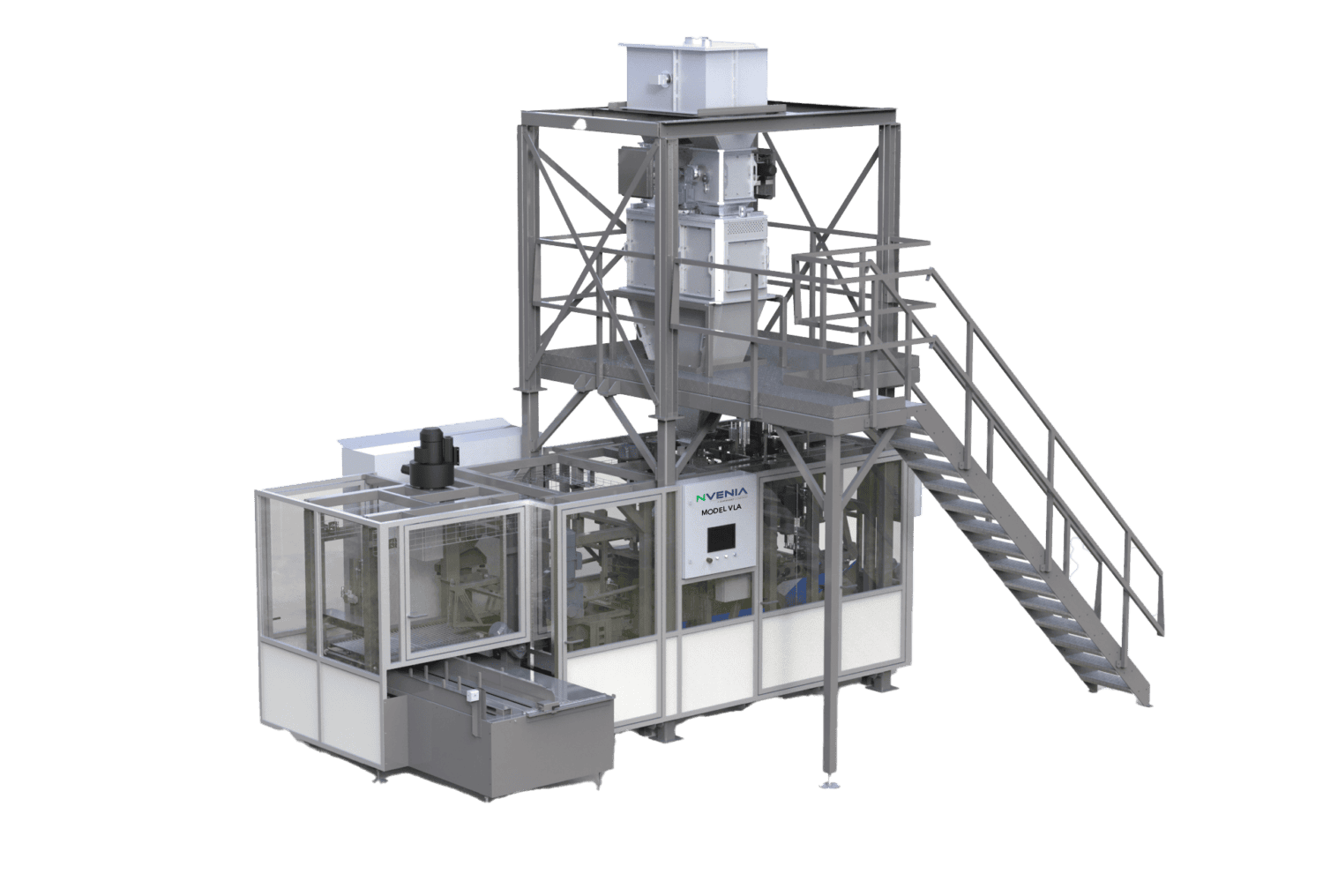

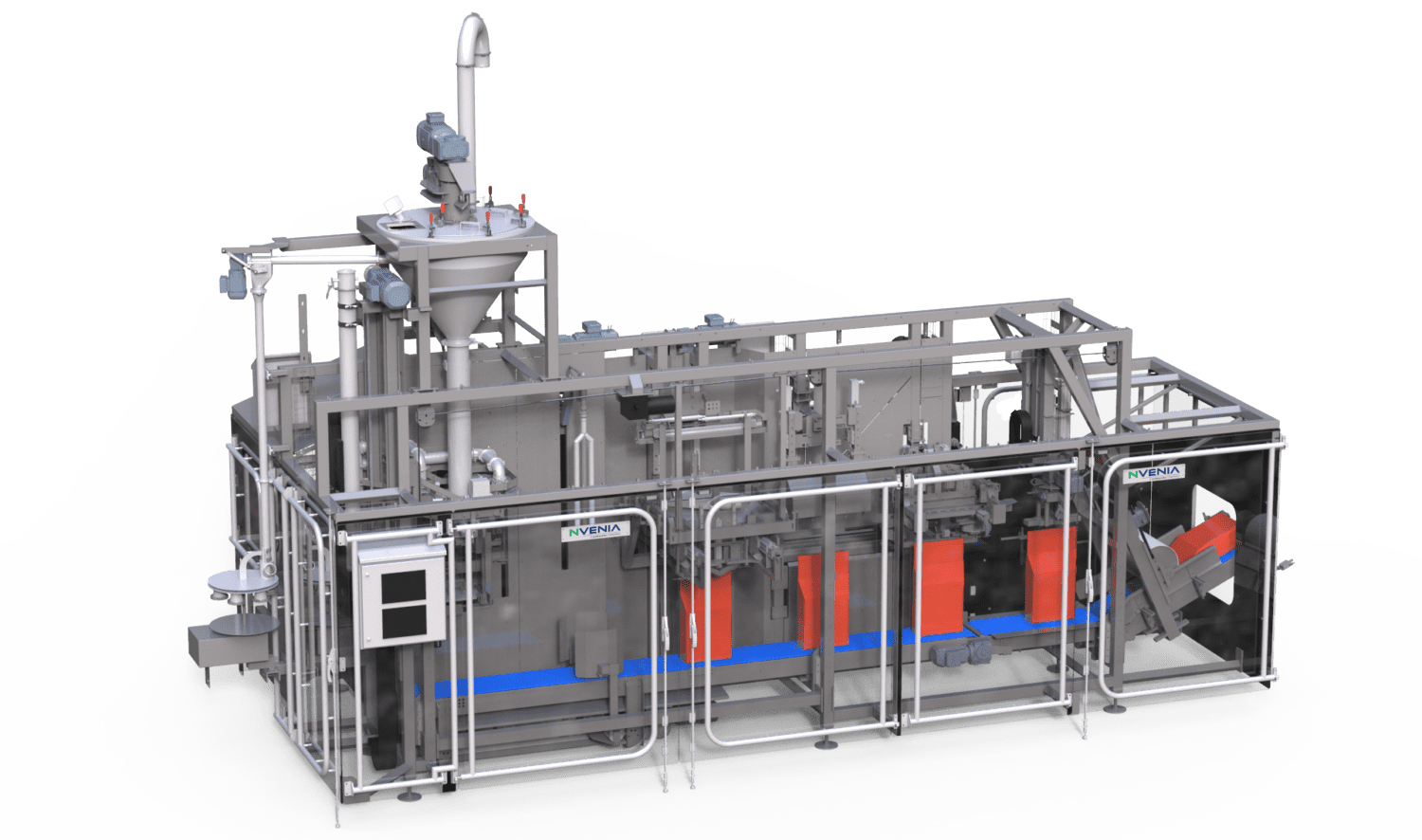

The nVenia VBA Model Tubular Film Bag Filling Machine is the fastest in our lineup of bagging machines, achieving up to 20 filled and sealed bags per minute. The VBA Model creates bags from either flat or side-gusseted tubular film and utilizes an innovative axial bag movement to minimize cycle times and increase rate. Because the VBA Model controls bag creation, features such as gusset corner seals, punched handles and bag perforations can be easily incorporated.

The VBA may be equipped with either a scale (gravity, vibratory, belt or horizontal auger fed) to dispense by weight, or with a volumetric filler. This makes the VBA Model ideal for accurately dispensing and bagging a broad array of both freely and poorly flowing materials. Agricultural products (seeds, nuts, beans), building materials (sand, gravel, lime) and animal feeds are just some of the products that the VBA Model Bag Filling Machine can easily handle.

Ease of operation and maintenance are the hallmarks of the VBA Model. Product changeovers are quick and require no mechanical adjustments. The VBA Model’s intuitive touchscreen interface allows for up to 500 programmable recipes for fast access and versatility of products.

Are you interested in this product?

We are here to help.

Features

- High precision weighing

- Capable of filling based on weight or volume

- Minimal headspace in filled bag

- Can incorporate bag features such as corner gusset seals and punched handles

- Low maintenance costs

- Easily accessible components for maintenance and cleaning

- Sturdily constructed for durability

- Simple product changeovers

- Offers 500 programmable recipes for enhanced customization

- Ethernet and WiFi connection for seamless connectivity

Standard Specs

Standard Specs

Speed

- Speed: Up to 20 bags per minute*

*Rate dependent on product characteristics and final weight in bag

Bag Information

Filled Bag Weight Range:

• 10 to 110 pounds

Bag Sizes (from Tubular Film Roll)

• Minimum: 11-3/8” Wide by 16-1/2” Long

• Maximum: 16-1/8” Wide by 35-3/8” Long

For Gusseted Tubular Roll:

• Minimum Gusset: 1-1/2”

• Maximum Gusset: 3-1/2”

Tubular Film Roll Maximum Diameter:

• 47-1/4”

Film Material:

• Polyethylene (PE

Electric & Air Requirements

- Electric: 460V-3Ph-60Hz

- Air: Air requirements dependent on selected options – consult factory

*Rate dependent on product characteristics and final weight in bag

Accessories

Accessories

OPTIONS:

- Bag de-aeration to improve stack stability during palletizing

- Inert gas purge to extend product shelf life

- Bag labeling or inkjet printing

- Bag handle punch

- Bag corner gusset seal

- Complete or partial implementation of stainless steel for corrosion-resistance

- Product presser for bulky products

*Some options may impact overall bagging rates