The Duravant family of operating companies serve the food processing, packaging and material handling segments.

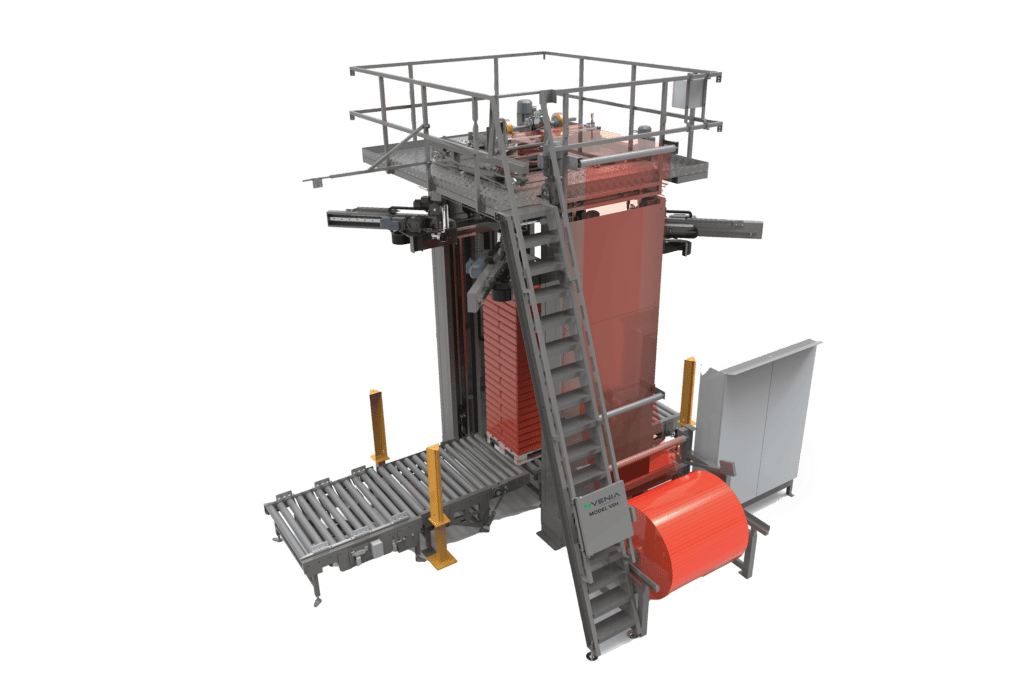

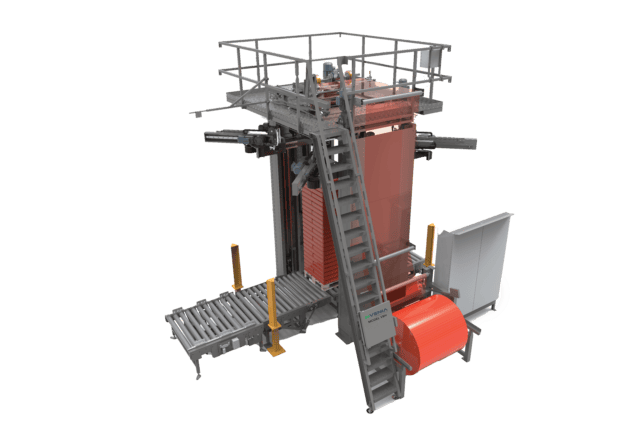

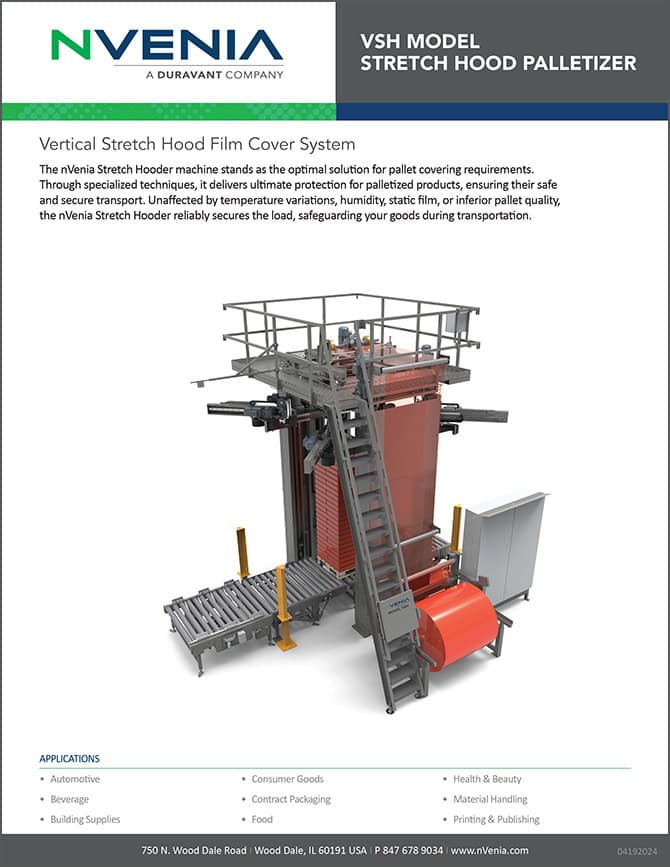

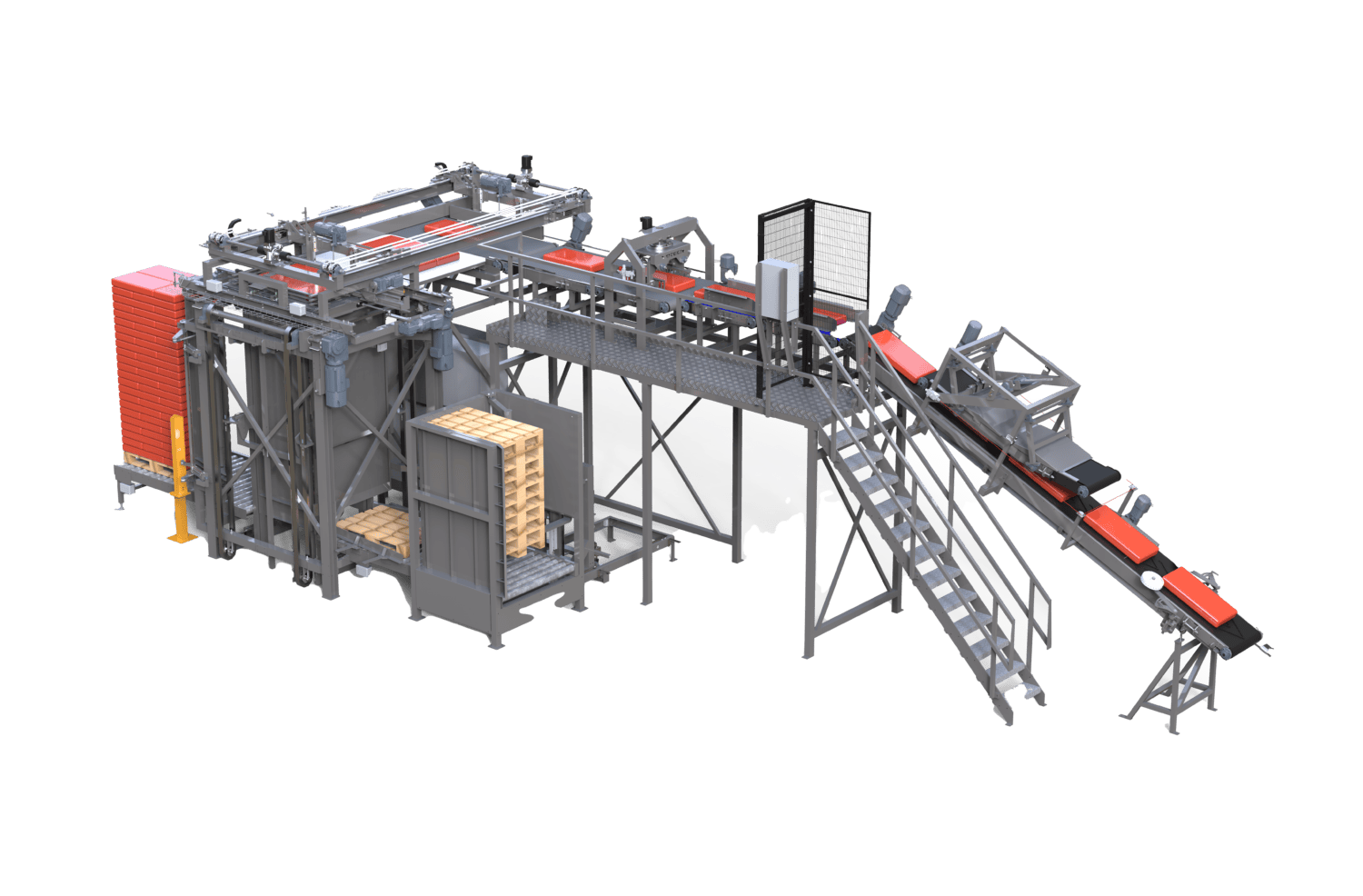

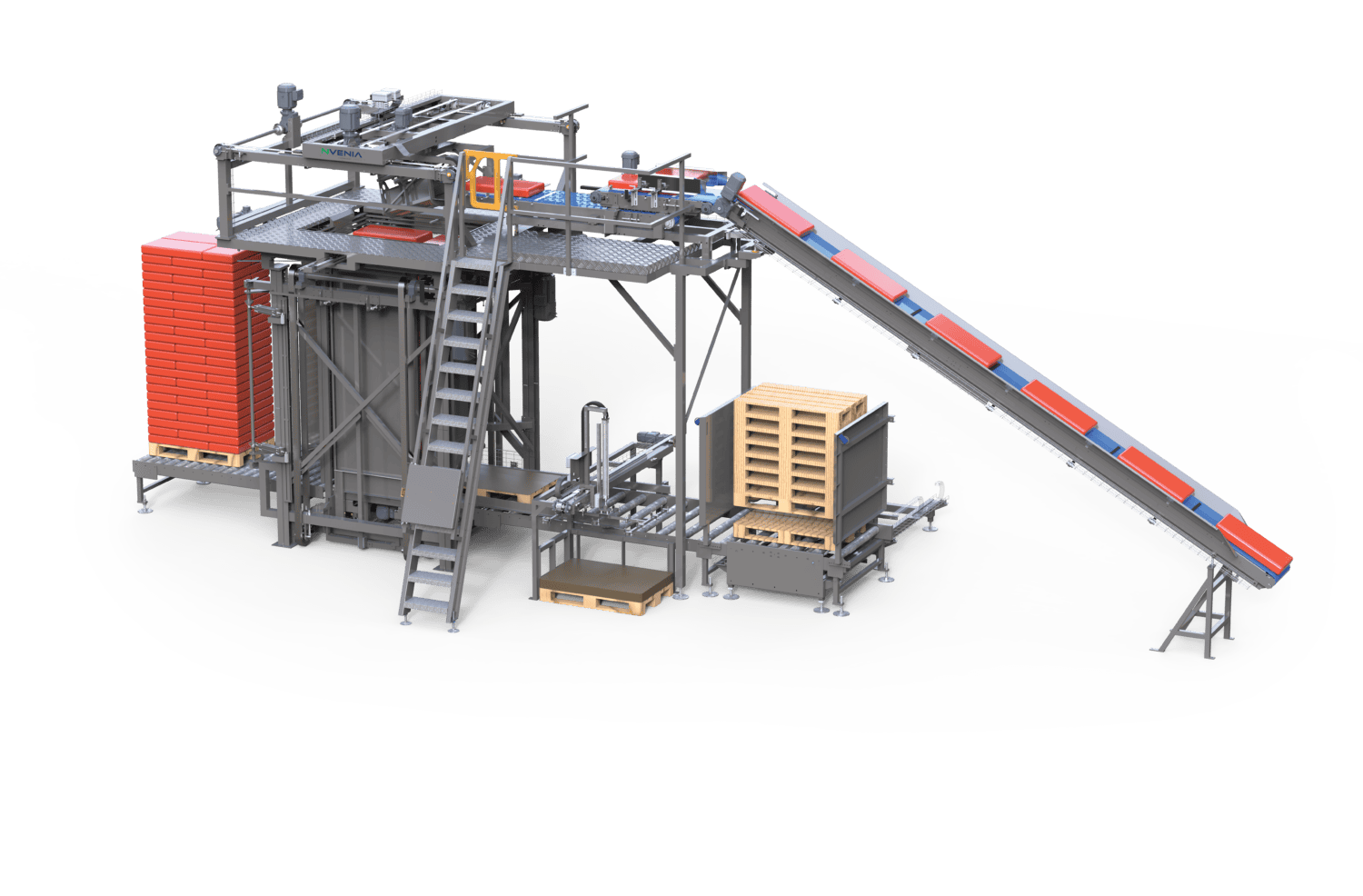

VSH Model Vertical Stretch Hood Film Cover System

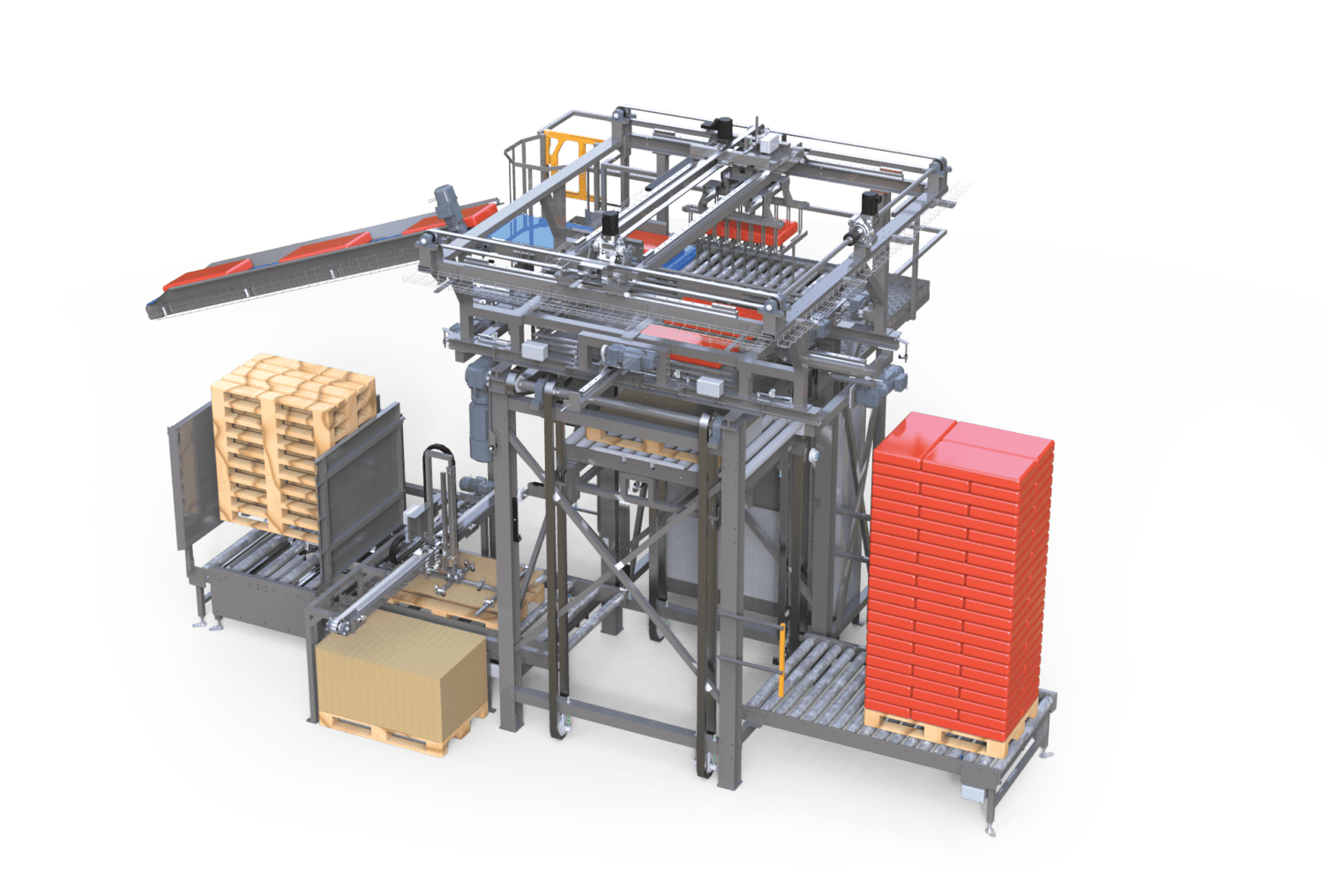

The nVenia VSH Stretch Hooder machine stands as the optimal solution for pallet covering requirements. Through specialized techniques, it delivers ultimate protection for palletized products, ensuring their safe and secure transit. Unaffected by temperature variations, humidity, static film, or inferior pallet quality, the Stretch Hooder reliably secures the load, safeguarding your goods during transportation.

Are you interested in this product?

We are here to help.

Features

- Automatically adjusts to accommodate various pallet sizes

- Achieves a 20% reduction in film usage through vertical stretching

- Utilizes mechanical opening of Stretch Hood film (non-vacuum method)

- Incorporates automatic pallet height measurement

- Features maintenance-free tension arms

- Pallet support is entirely driven by roller conveyors

- Easily expandable with additional foil rolls for different pallet sizes

- Offers separate automatic tension arm correction

- Frequency-controlled tension arms, individually adjustable

- User-friendly operation

- Includes 500 adjustable menu options

- Requires minimal maintenance

- Equipped with Ethernet connection and Wi-Fi capabilities

Standard Specs

Standard Specs

Capacity

- 100 Pallets/hour

Electrical Requirements

- 460V, 3Ph, 60Hz

Pallet Sizes

- Standard: 48″x32″

- Industrial: GMA & CHEP 40″x48″

* not limited to U.S. pallets

Accessories

Accessories

OPTIONS:

- Several film rolls (different type or size of the film)

- Pallet correction within machine or at infeed position

- Unit for creating de-aeration (warm products)