The Duravant family of operating companies serve the food processing, packaging and material handling segments.

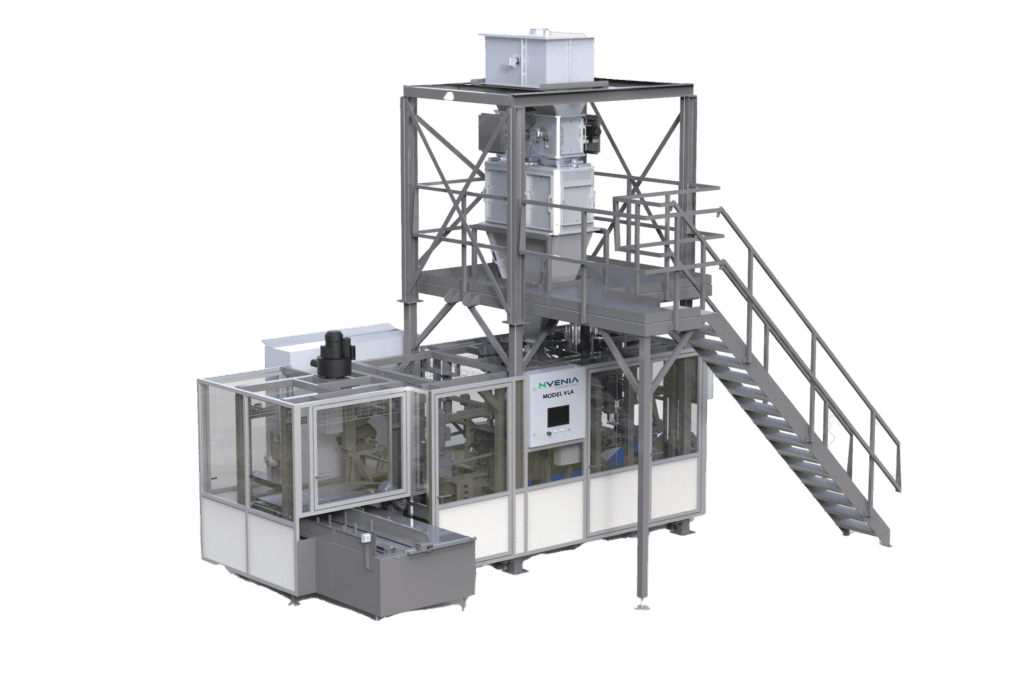

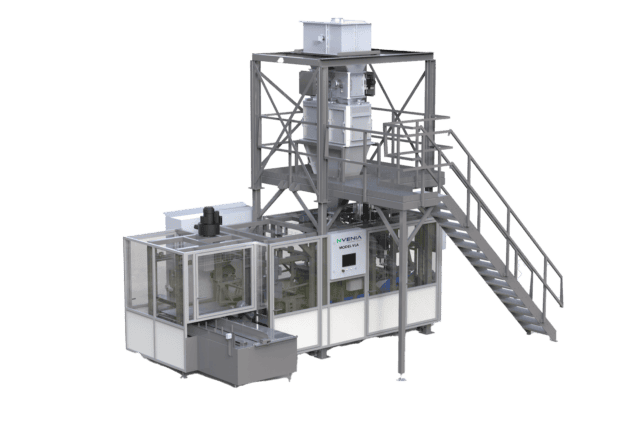

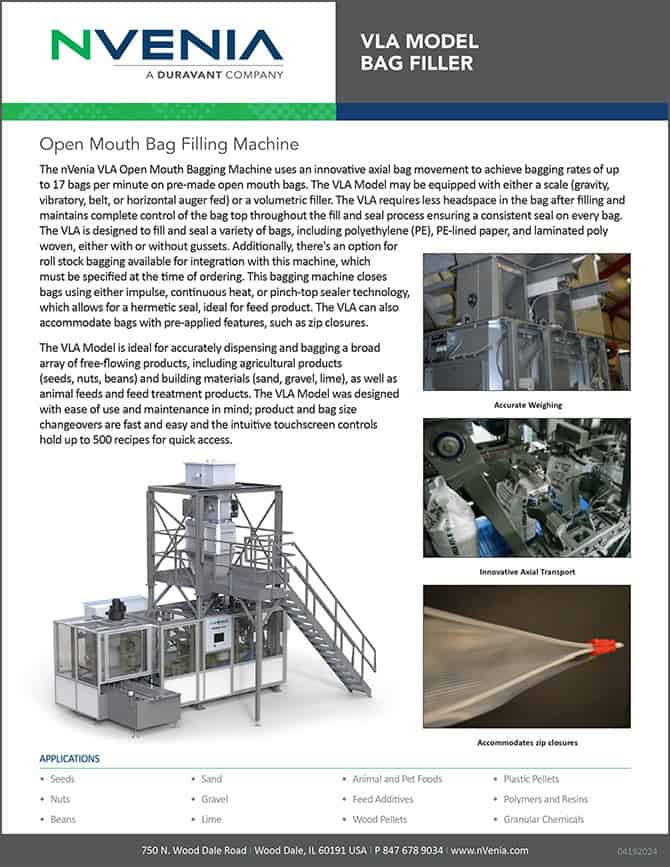

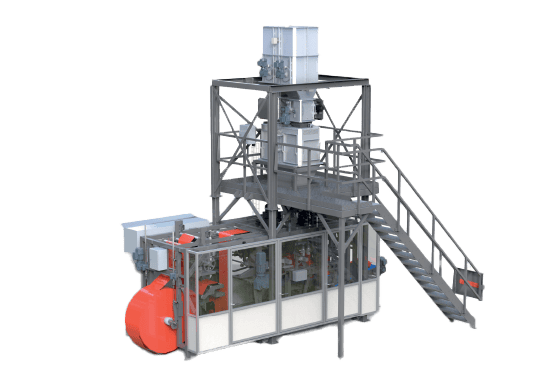

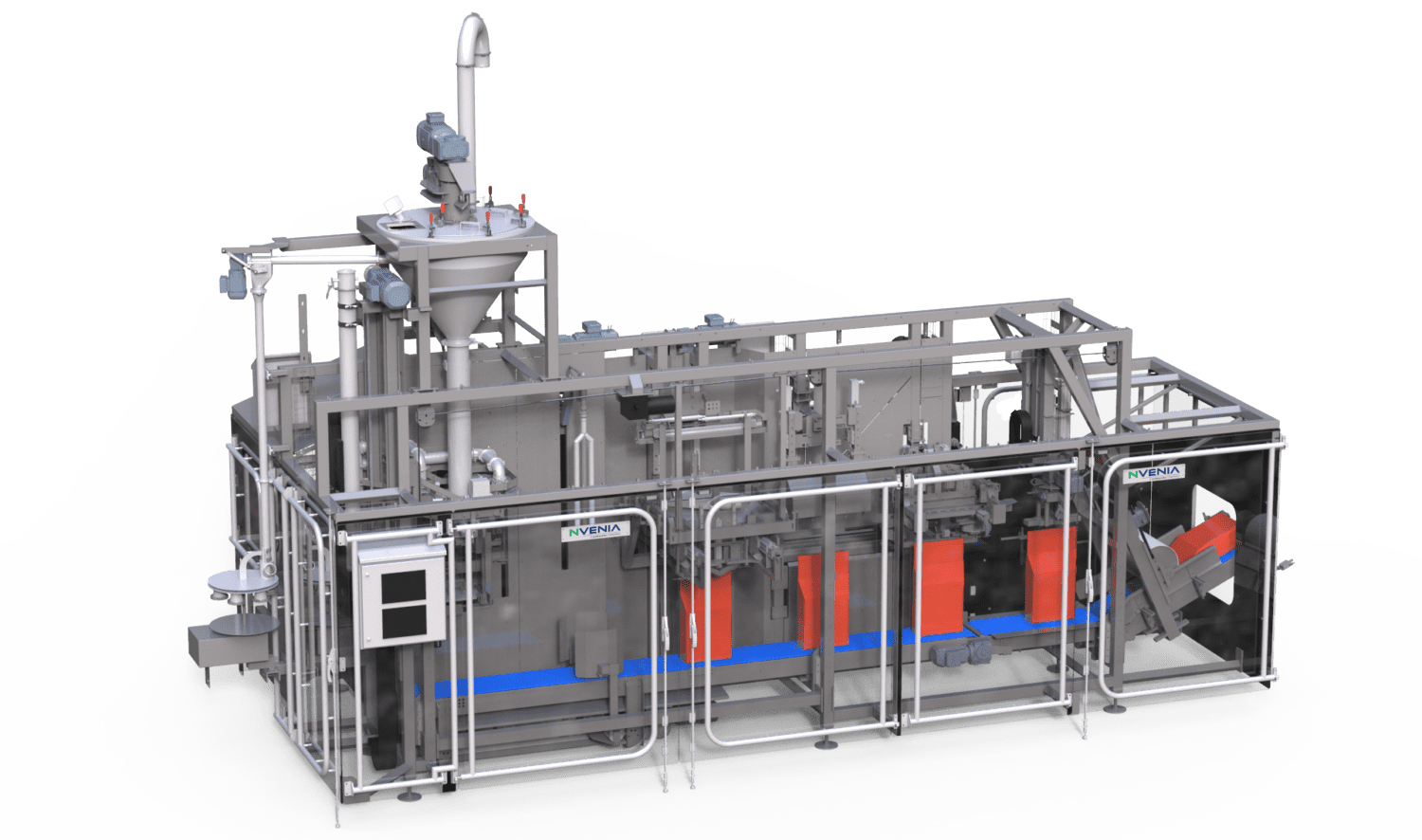

VLA Model Open Mouth Bag Filling Machine

The nVenia VLA Open Mouth Bagging Machine uses an innovative axial bag movement to achieve bagging rates of up to 17 bags per minute on pre-made open mouth bags. The VLA Model may be equipped with either a scale (gravity, vibratory, belt, or horizontal auger fed) or a volumetric filler. The VLA requires less headspace in the bag after filling and maintains complete control of the bag top throughout the fill and seal process ensuring a consistent seal on every bag. The VLA is designed to fill and seal a variety of bags, including polyethylene (PE), PE-lined paper, and laminated poly woven, either with or without gussets.

Additionally, there’s an option for roll stock bagging available for integration with this machine, which must be specified at the time of ordering. This bagging machine closes bags using either impulse, continuous heat, or pinch-top sealer technology, which allows for a hermetic seal, ideal for feed product. The VLA can also accommodate bags with pre-applied features, such as zip closures.

The VLA Model is ideal for accurately dispensing and bagging a broad array of free-flowing products, including agricultural products (seeds, nuts, beans) and building materials (sand, gravel, lime), as well as animal feeds and feed treatment products. The VLA Model was designed with ease of use and maintenance in mind; product and bag size changeovers are fast and easy and the intuitive touchscreen controls hold up to 500 recipes for quick access.

Are you interested in this product?

We are here to help.

Features

- Consistent, perfectly placed straight seals due to bag transport technology

- Minimizes headspace in filled bag

- Accommodates bags with pre-made closures

- Quickly and easily adjustable for bag size changeovers

- Capable of dosing based on weight or volume

- Sturdily constructed for durability

- Built for serviceability and ease of maintenance

- Offers 500 programmable recipes for enhanced customization

- Equipped with Ethernet connection and WiFi capability for seamless connectivity

Standard Specs

Standard Specs

Speed

- Speed: Up to 17 bags per minute*

* Rate dependent on product characteristics and final weight in bag

Bag Information

Empty Bag Size Range*:

- Minimum: 11-1/4″ wide by 16-1/2″ long

(if gusseted, minimum of 7-1/8″ is req between gussets) - Maximum: 16-1/8″ wide by 35-3/8″ long

*Consult your regional sales manager for bags outside of provided range

Filled Bag Weight Range:

- 10 to 110 pounds

Variety of Integrated Bag Sealing Solutions

- Impulse Sealing

- Continuous Heat Sealing

- Pinch-top Sealing

Electric & Air Requirements

- Electric: 460V-3Ph-60Hz

- Air: Air requirements dependent on required options

– Consult factory

Accessories

Accessories

OPTIONS:

- Ribbed Heat Seal

- Bag de-aeration to improve stack stability during palletizing

- Inert gas purge to improve product shelf life

- Bag labeling or inkjet printing

- Complete or partial implementation of stainless steelfor corrosion-resistance

- Addition of tubular film roll

*Some options may impact overall bagging rates