The Duravant family of operating companies serve the food processing, packaging and material handling segments.

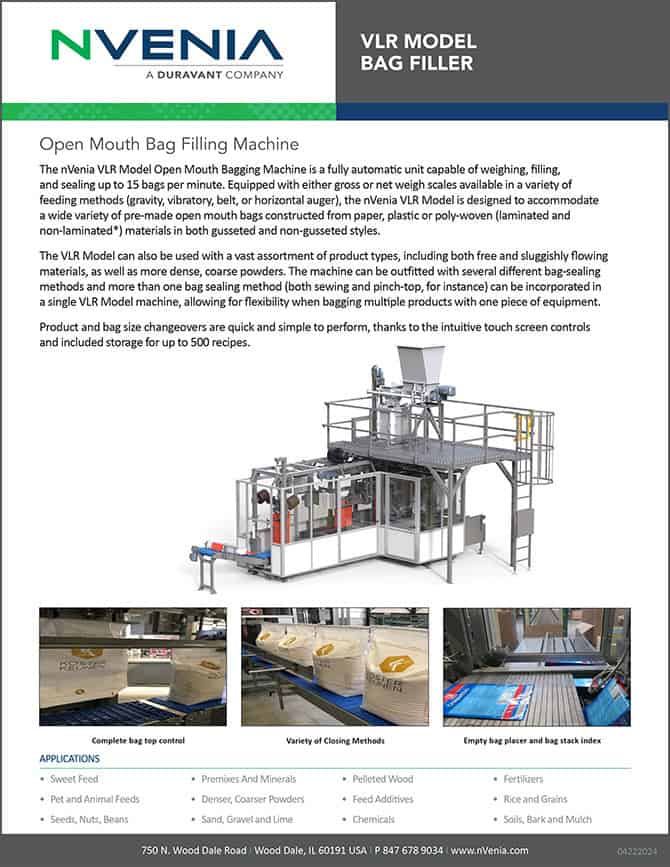

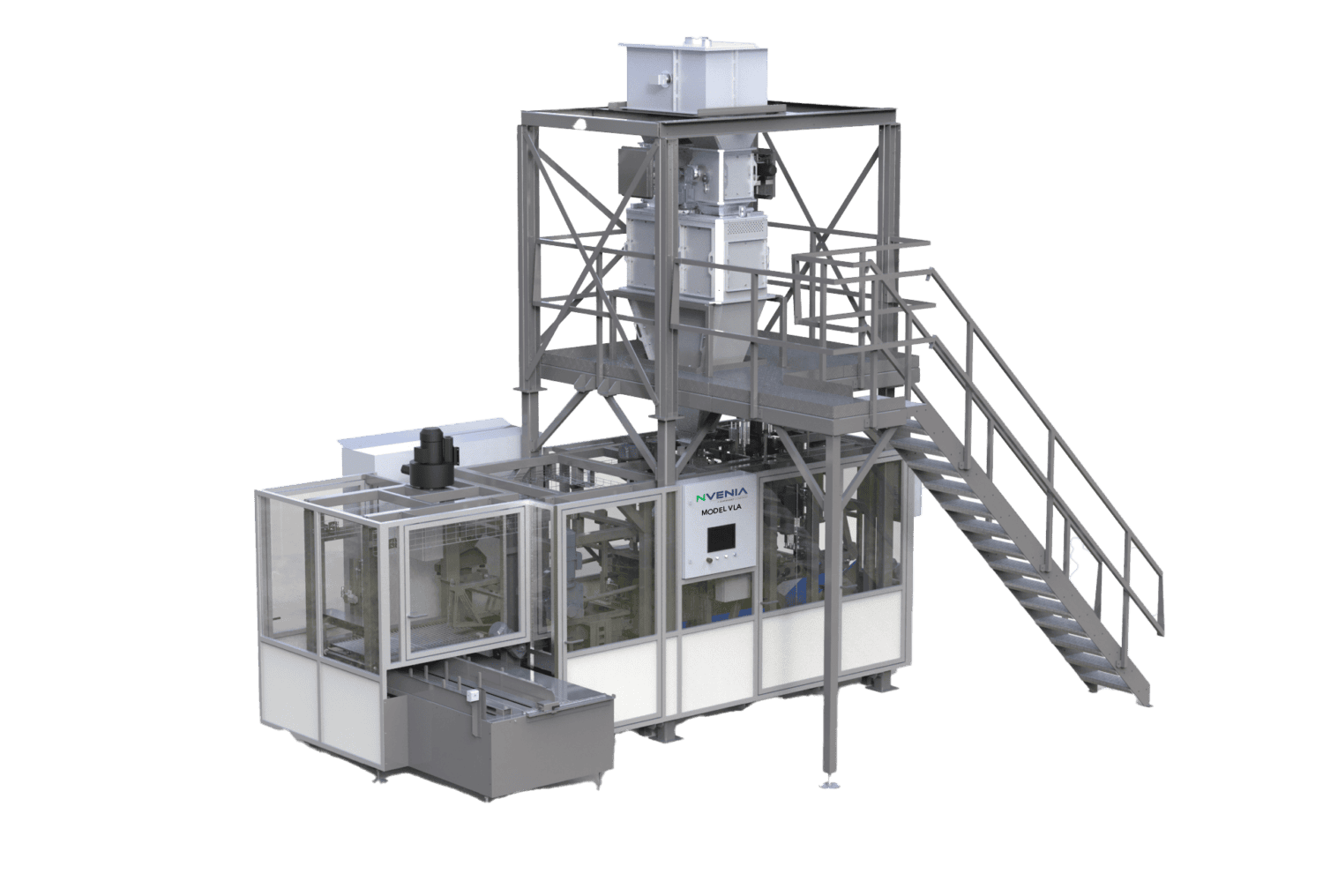

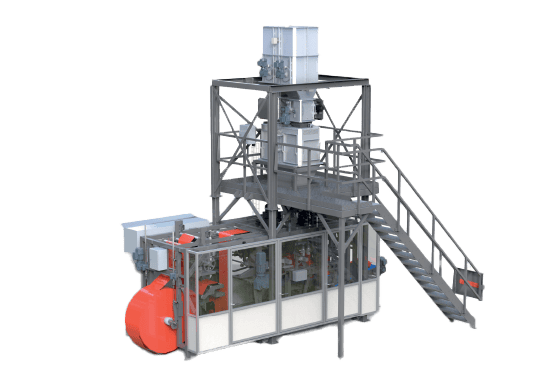

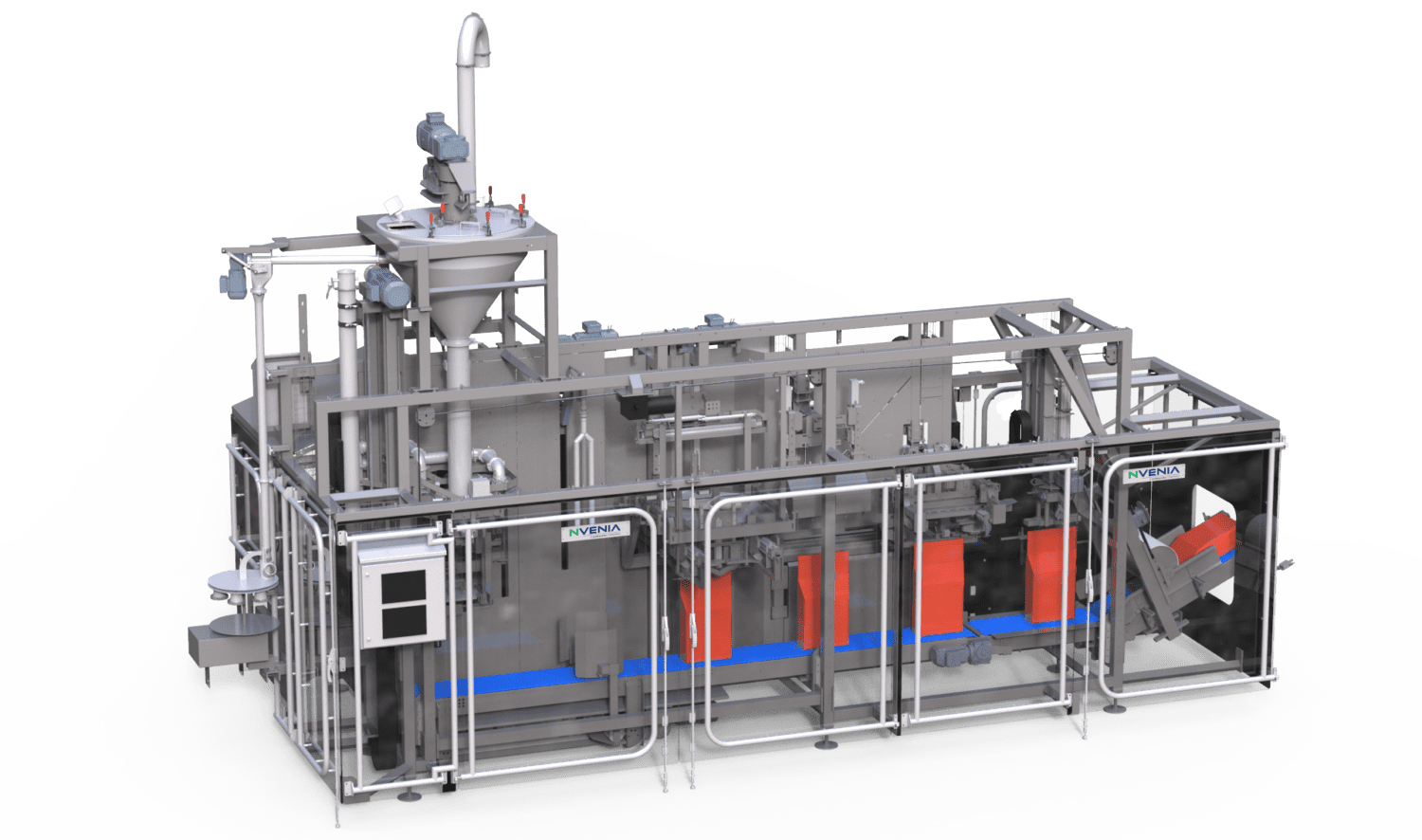

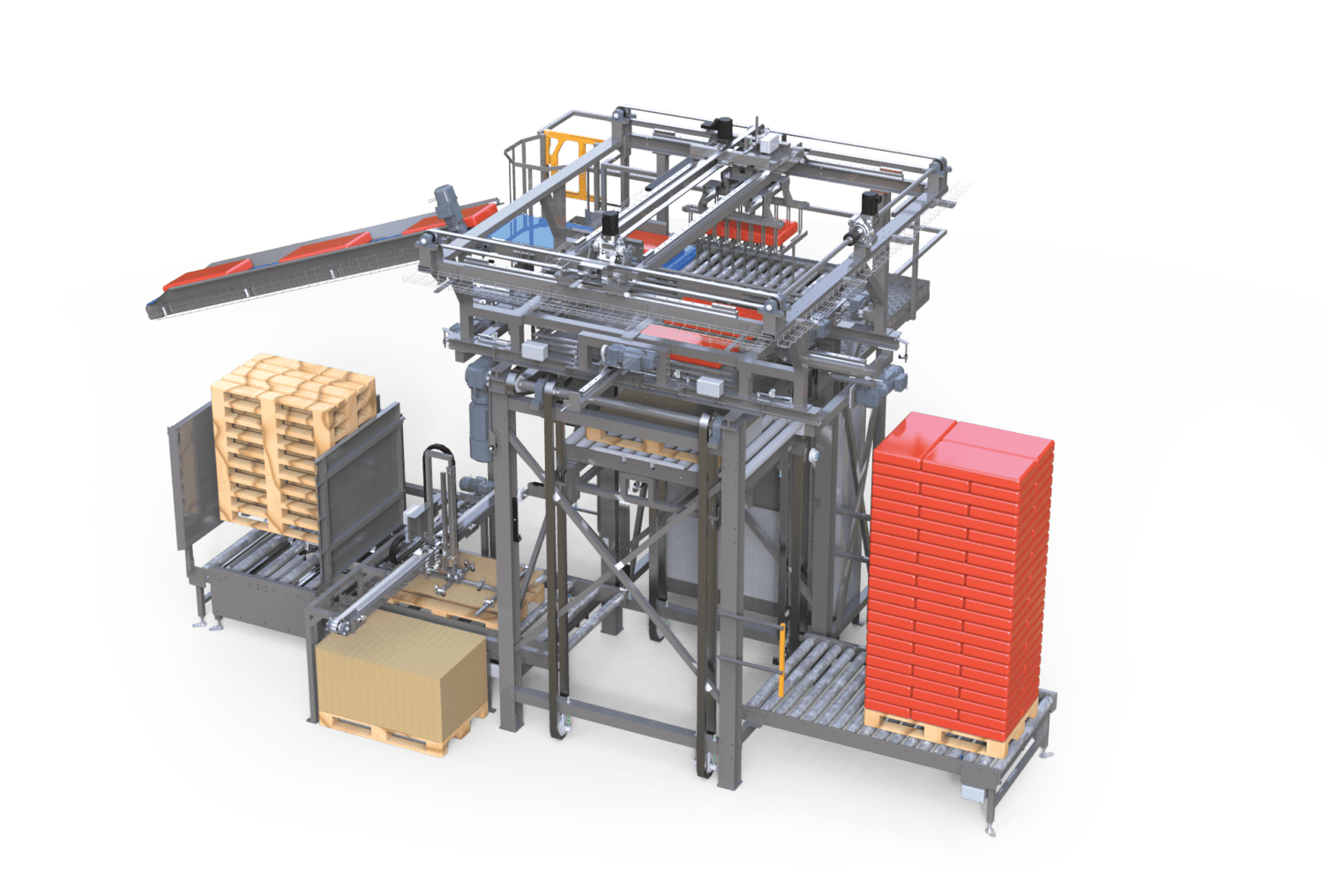

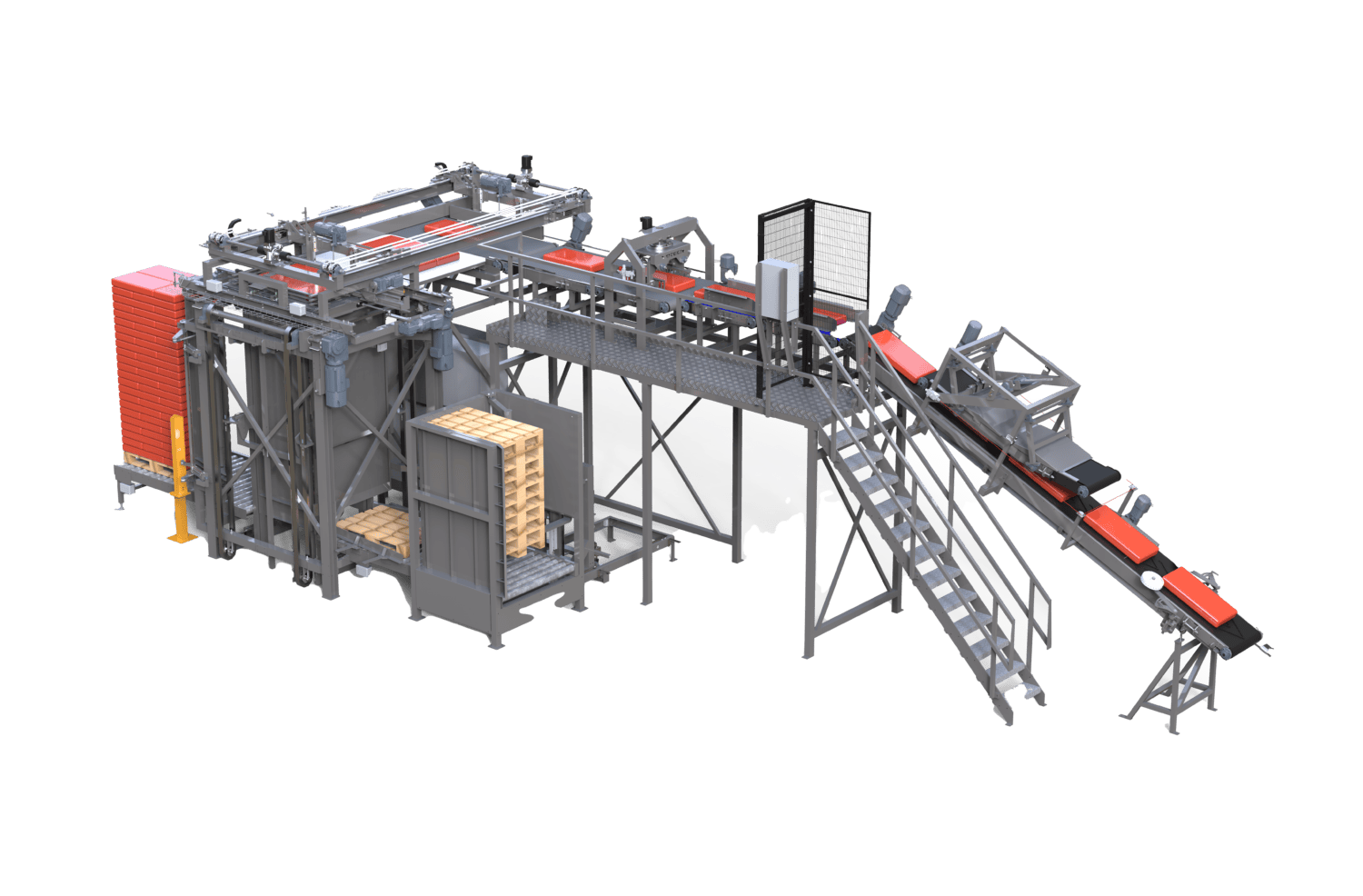

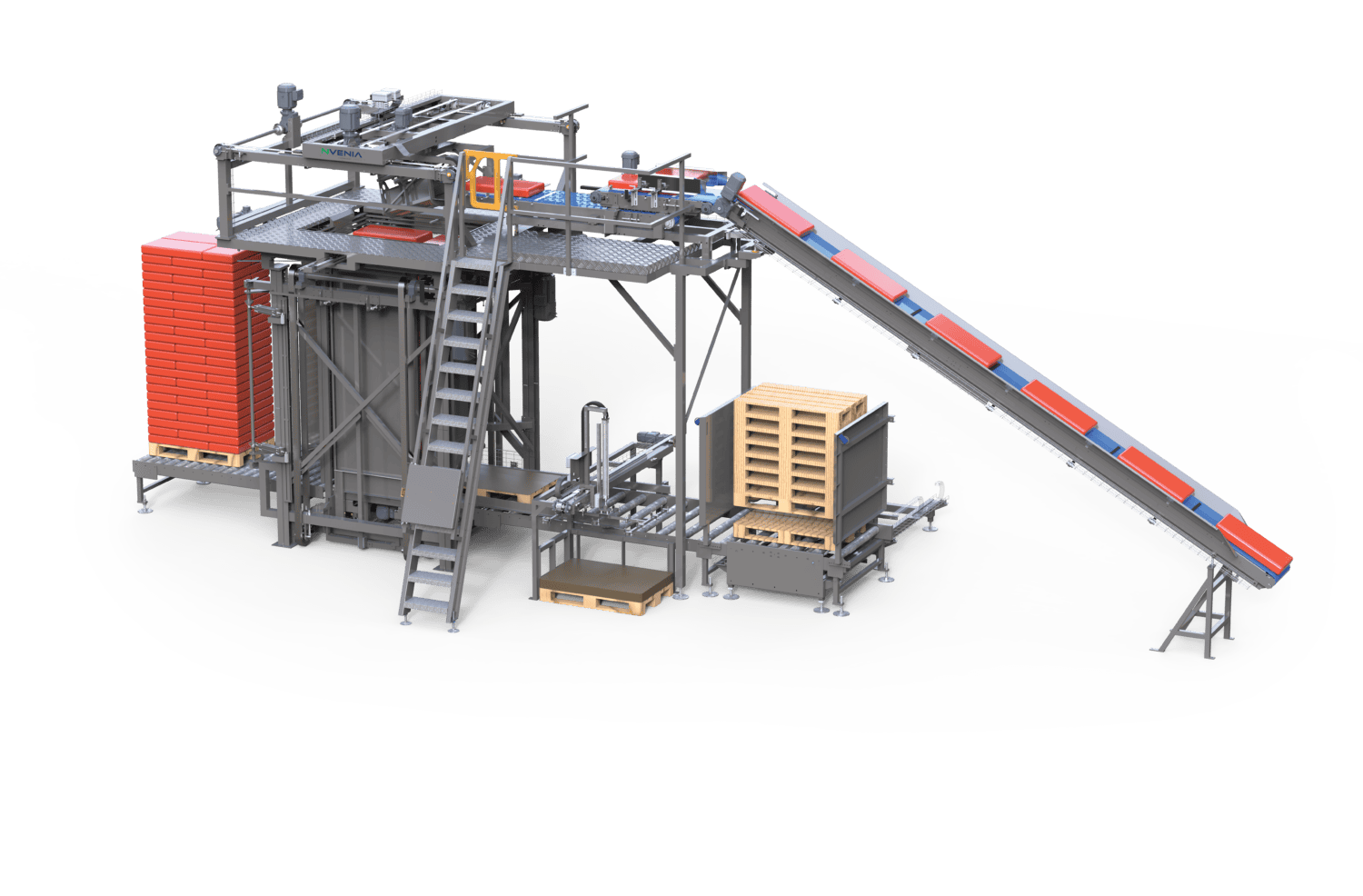

VLR Model Open Mouth Bag Filling Machine

The nVenia VLR Model Open Mouth Bagging Machine is a fully automatic unit capable of weighing, filling, and sealing up to 15 bags per minute. Equipped with either gross or net weigh scales available in a variety of feeding methods (gravity, vibratory, belt, or horizontal auger), the nVenia VLR Model is designed to accommodate

a wide variety of pre-made open mouth bags constructed from paper, plastic or poly-woven (laminated and non-laminated*) materials in both gusseted and non-gusseted styles.

The VLR Model can also be used with a vast assortment of product types, including both free and sluggishly flowing materials, as well as more dense, coarse powders. The machine can be outfitted with several different bag-sealing methods and more than one bag sealing method (both sewing and pinch-top, for instance) can be incorporated in a single VLR Model machine, allowing for flexibility when bagging multiple products with one piece of equipment.

Product and bag size changeovers are quick and simple to perform, thanks to the intuitive touch screen controls and included storage for up to 500 recipes.

Are you interested in this product?

We are here to help.

Features

- Ideal for both free-flowing and poorly flowing products

- Capable of dosing based on weight or volume

- Sturdily constructed for durability

- Built for serviceability and ease of maintenance

- Offers 500 programmable recipes for enhanced customization

- Requires minimal maintenance

- Features Ethernet connection and Wi-Fi capabilities for seamless connectivity

Standard Specs

Standard Specs

Speed

- Speed: Up to 15 bags per minute*

*Rate dependent on product characteristics and final weight requirements

Electric & Air Requirements

- Electric: 460V-3Ph-60Hz

- Air: Air requirements dependent on selected options

Variety of Integrated Bag Sealing Methods

- Pinch-Top sealing

- Zip closure

- Sealing

- Sewing (with or without crêpe tape and single folding)

- Combination Pinch-Top, sealing and sewing inside one machine is also possible

Bag Information

Empty Bag Size Range*:

• Minimum: 16” wide by 23-5/8” long

(if gusseted, minimum of 10-1/4” is req b/w gussets)

• Maximum: 22-3/8” wide by 39-3/8” long

*Consult your regional sales manager for bags outside of provided range

Filled Bag Weight Range:

• 10 to 110 pounds

Bag Types

- Paper

- Plastic

- Poly-woven (laminated and non-laminated*)

*Non-laminated poly-woven bags are subject to review and acceptance prior to placement of order

Accessories

Accessories

OPTIONS:

- Bag de-aeration to improve stack stability during palletization

- Inert gas purge to improve product shelf life

- Automatic product sampling

- Bag labelling or inkjet printing

- Complete or partial implementation of stainless steel for corrosion resistance

- Metal detectors

- Filled bag checkweighers

*Some options may impact overall bagging rate