The Duravant family of operating companies serve the food processing, packaging and material handling segments.

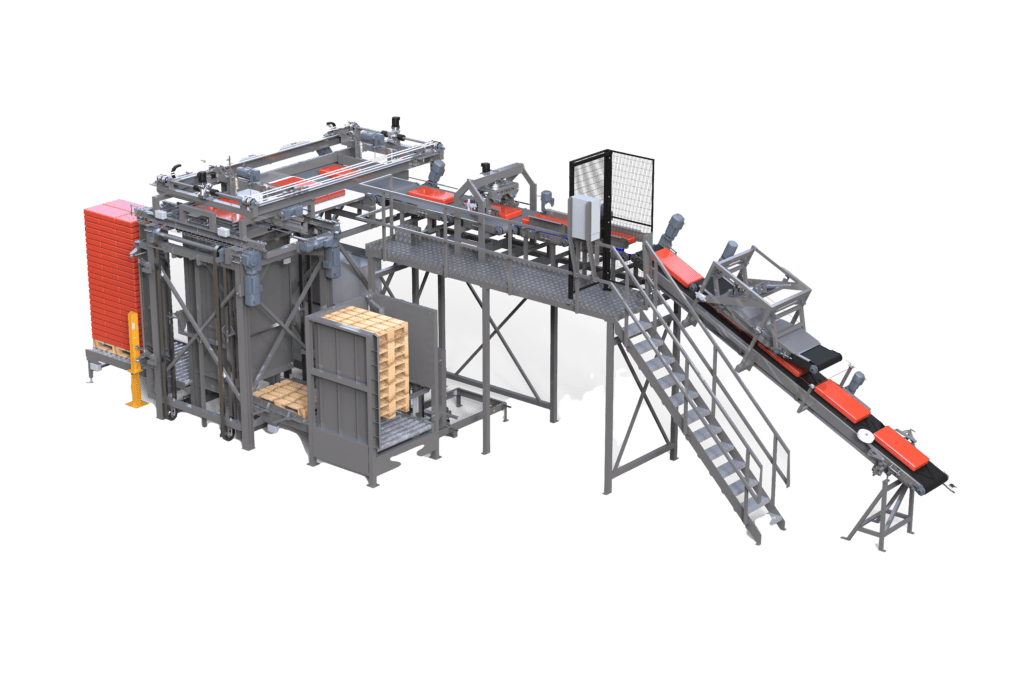

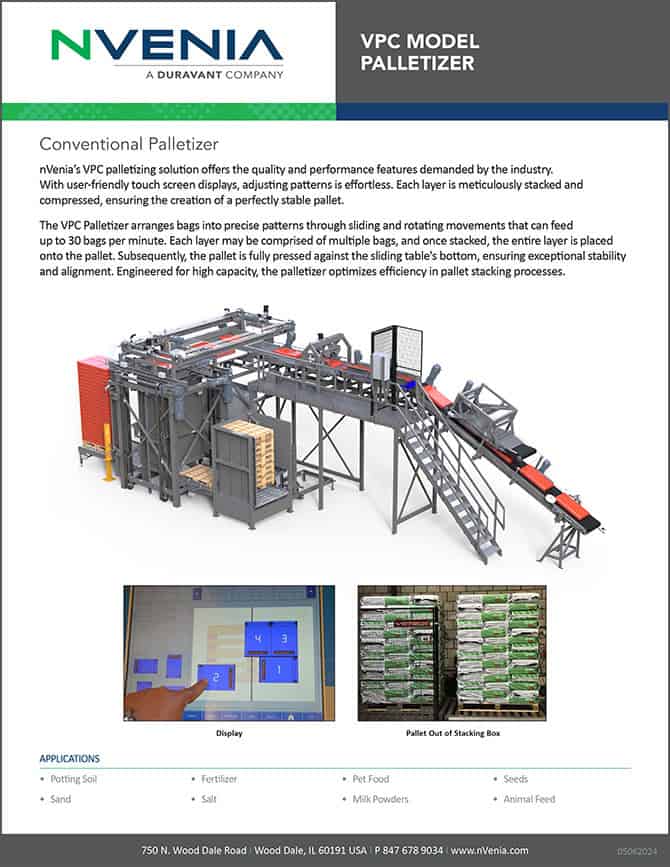

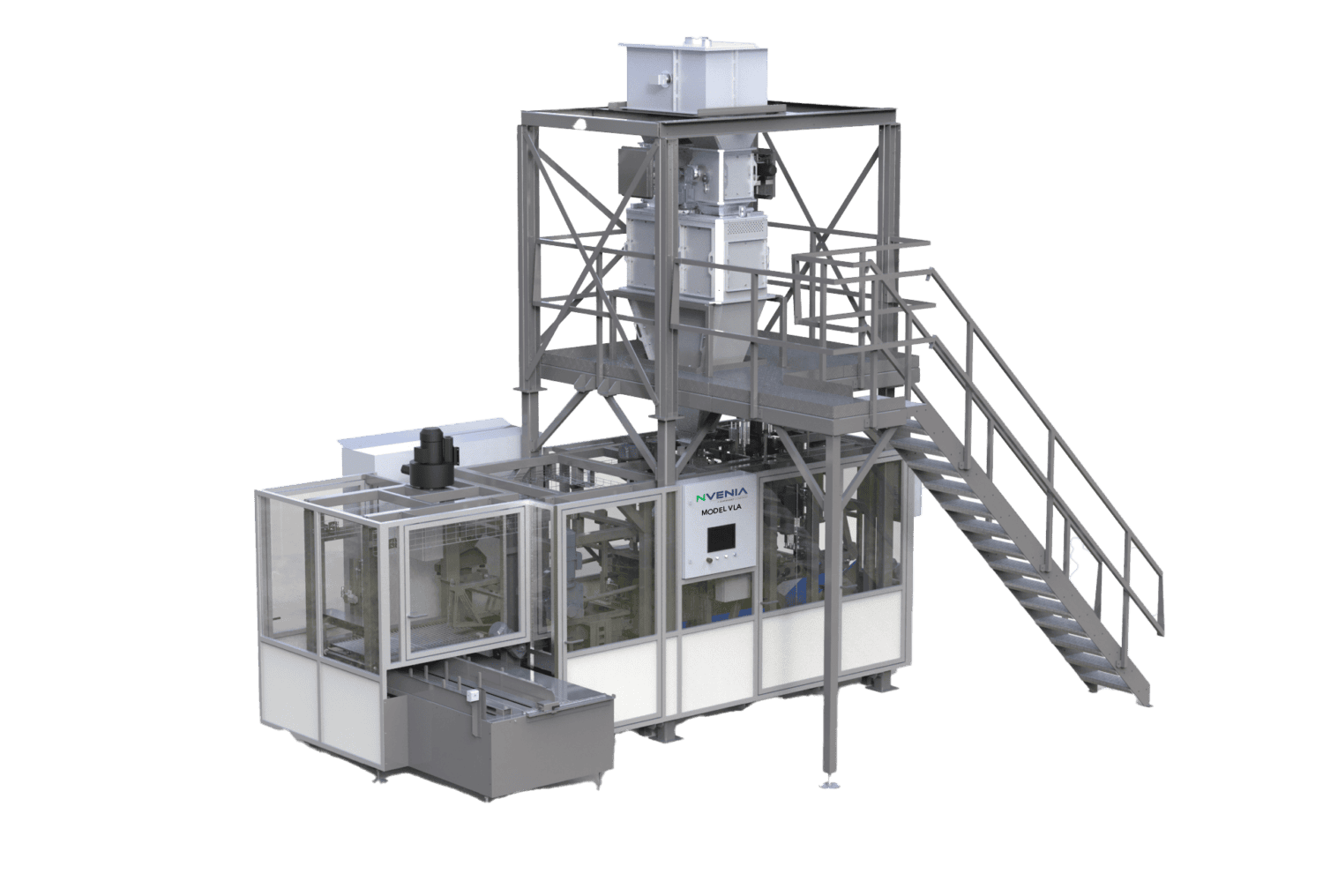

VPC Model Conventional Palletizer

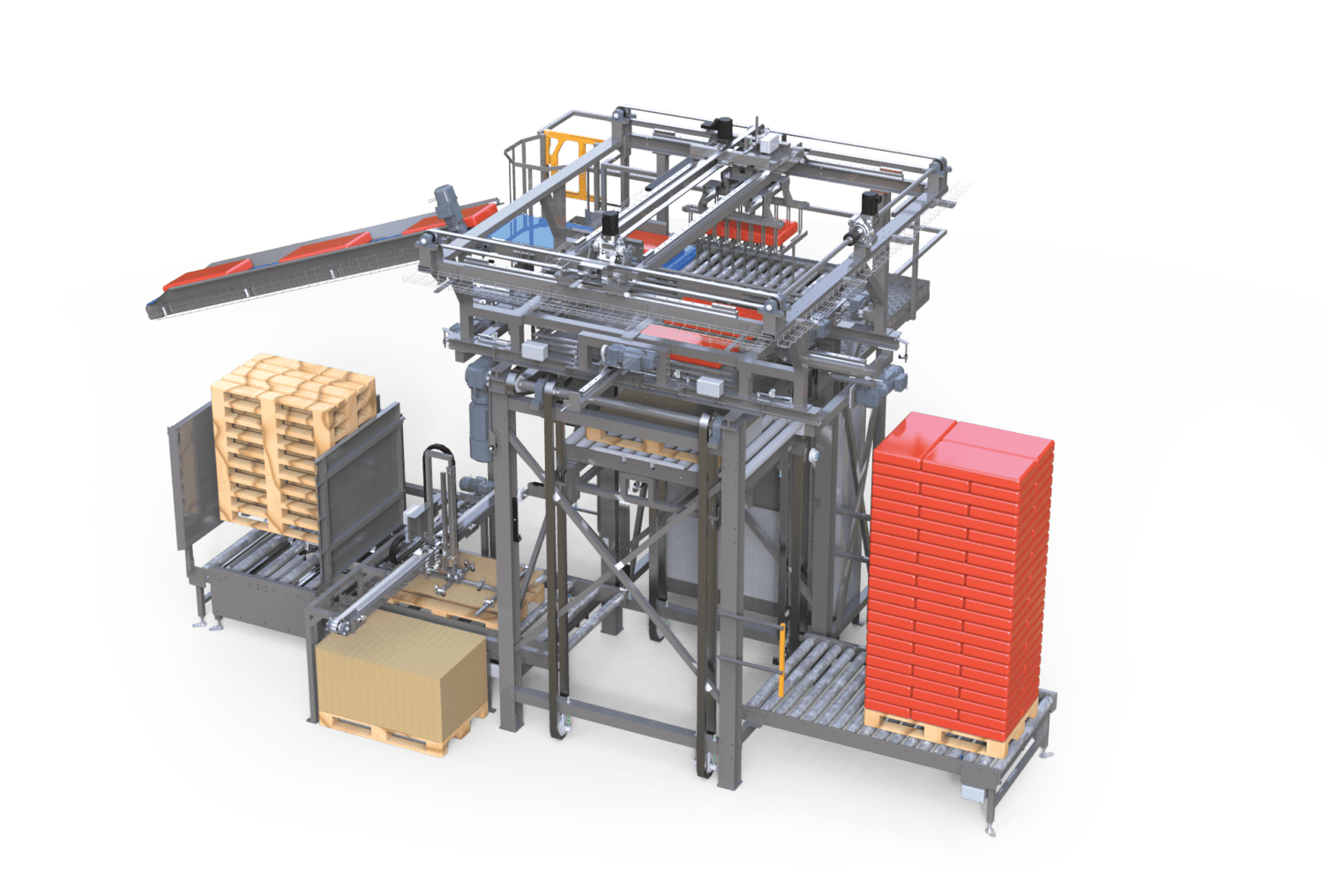

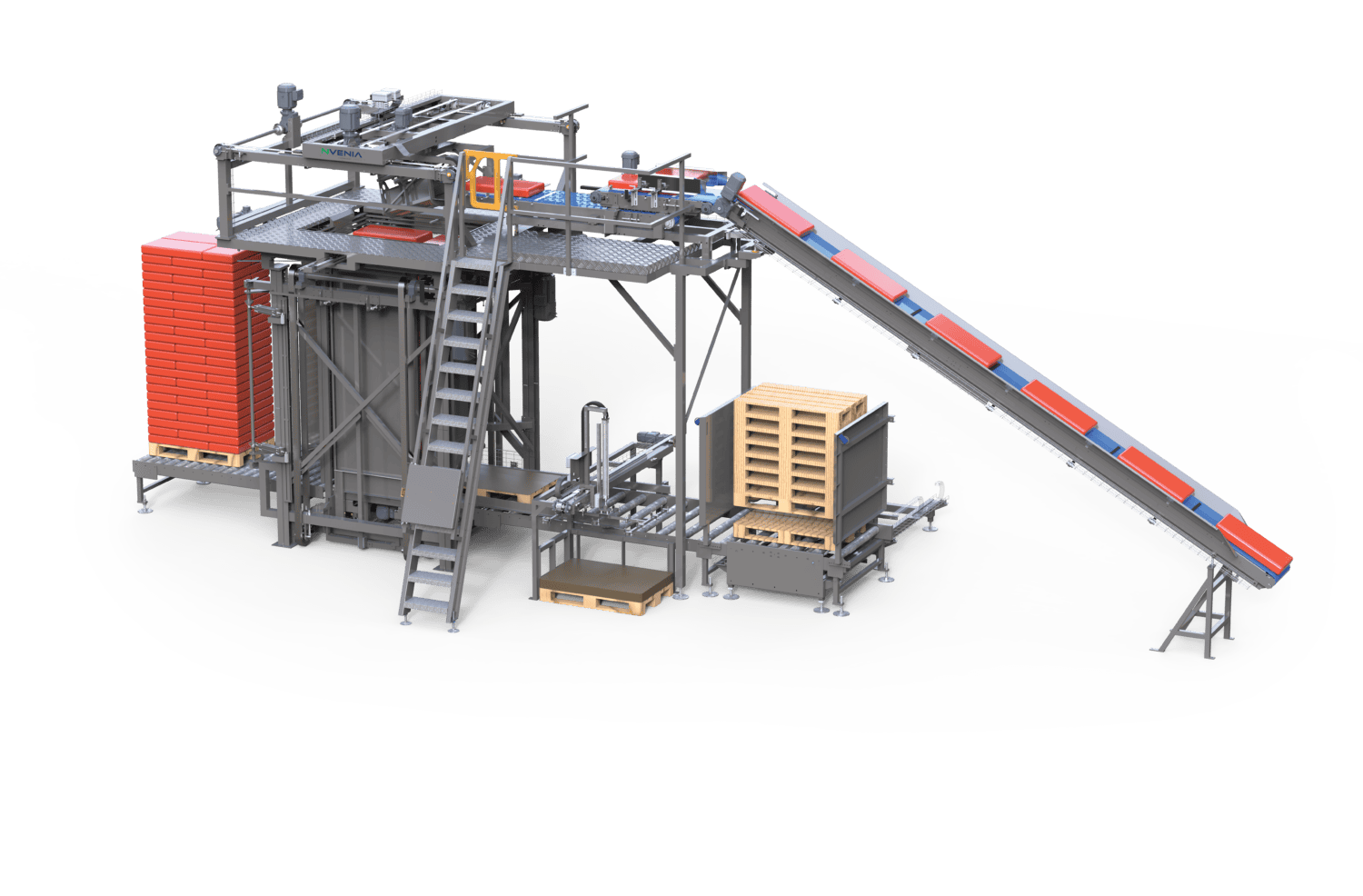

nVenia’s VPC palletizing solution offers the quality and performance features demanded by the industry. With user-friendly touch screen displays, adjusting patterns is effortless. Each layer is meticulously stacked and compressed, ensuring the creation of a perfectly stable pallet.

The VPC Palletizer arranges bags into precise patterns through sliding and rotating movements that can feed up to 30 bags per minute. Each layer may be comprised of multiple bags, and once stacked, the entire layer is placed onto the pallet. Subsequently, the pallet is fully pressed against the sliding table’s bottom, ensuring exceptional stability and alignment. Engineered for high capacity, the palletizer optimizes efficiency in pallet stacking processes.

Are you interested in this product?

We are here to help.

Features

- Bag patterns can be easily adjusted through the display interface

- Compatible with conventional stacking methods

- Sturdily constructed with complete motor-driven functionality

- Press time per layer can be independently configured

- Suitable for various packaging types including bags, boxes, and crates

- Compatible with multiple pallet sizes

- Includes 500 programmable menus

- Requires minimal maintenance

- Equipped with Ethernet connection for seamless integration

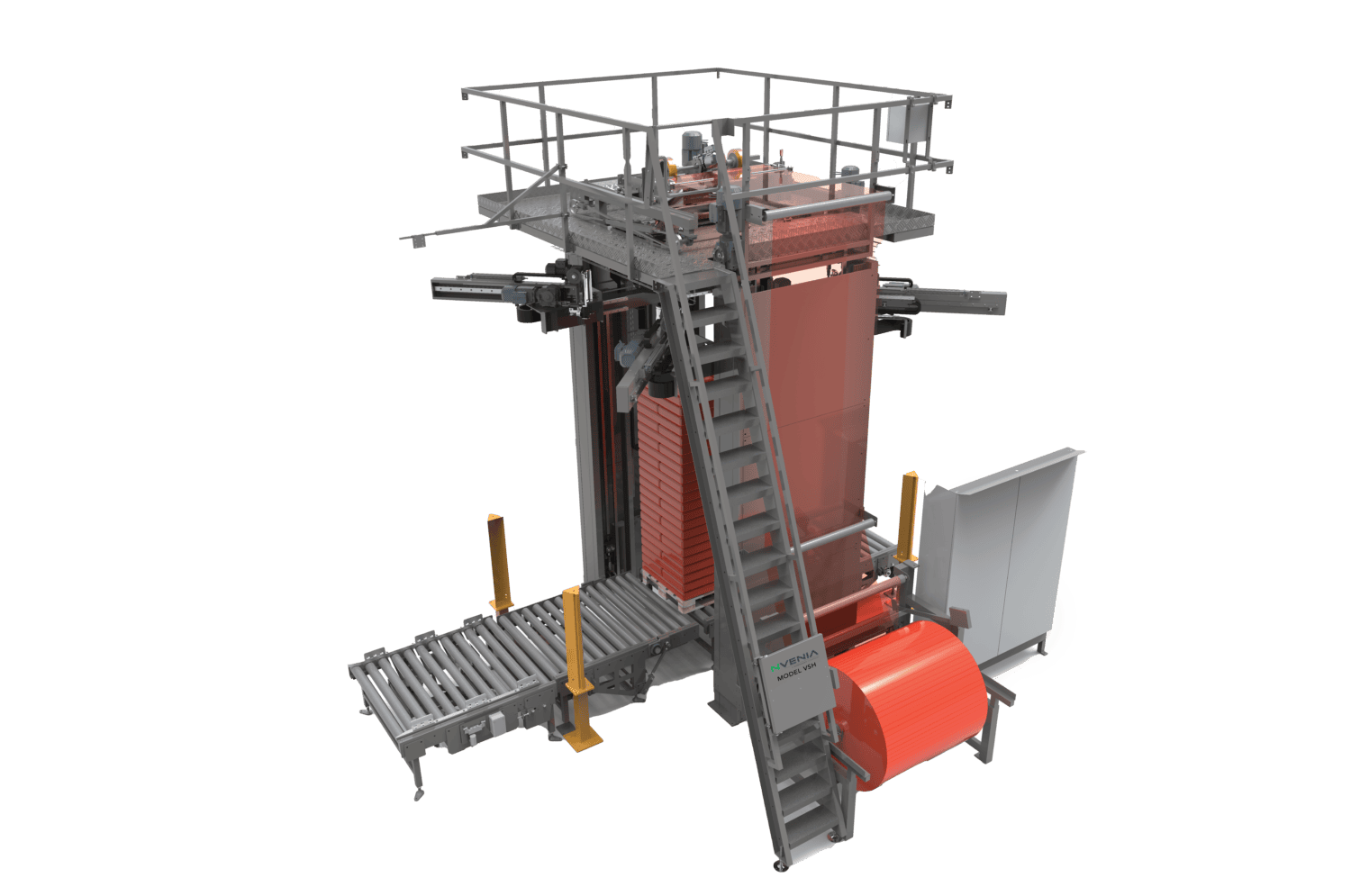

Standard Specs

Standard Specs

Type

- Type: Conventional

Bag Weight

- 10-110 lbs.

Electrical Requirements

- 460V, 3Ph, 60Hz

Pallet Sizes

- Standard: 48″x32″

- Industrial: GMA & CHEP 40″x48″

* not limited to U.S. pallets

Accessories

Accessories

OPTIONS:

- Stacking box (several pallet sizes)

- Sheet dispenser (paper, film)

- Air support for minimal friction during bag sliding

- Inclined conveyor (with equalizer rolls)

- Bag flattener to compress the product