The Duravant family of operating companies serve the food processing, packaging and material handling segments.

EXTREME XF Model Air Shrink Wrap System

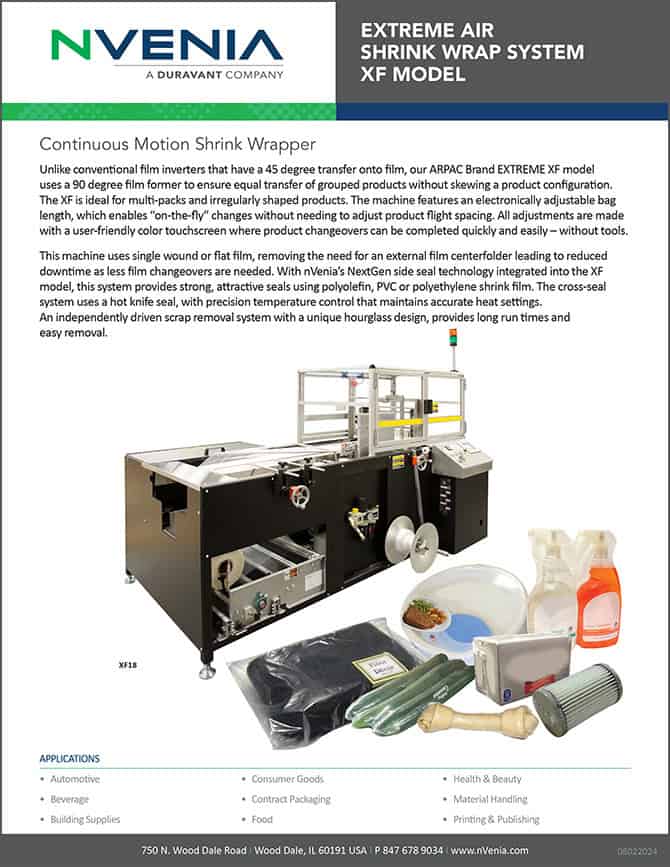

Unlike conventional film inverters that have a 45 degree transfer onto film, our ARPAC Brand EXTREME XF model uses a 90 degree film former to ensure equal transfer of grouped products without skewing a product configuration. The XF is ideal for multi-packs and irregularly shaped products. The machine features an electronically adjustable bag length, which enables “on-the-fly” changes without needing to adjust product flight spacing. All adjustments are made with a user-friendly color touchscreen where product changeovers can be completed quickly and easily – without tools.

This machine uses single wound or flat film, removing the need for an external film centerfolder leading to reduced downtime as less film changeovers are needed. With nVenia’s NextGen side seal technology integrated into the XF model, this system provides strong, attractive seals using polyolefin, PVC or polyethylene shrink film. The cross-seal system uses a hot knife seal, with precision temperature control that maintains accurate heat settings. An independently driven scrap removal system with a unique hourglass design, provides long run times and easy removal.

Are you interested in this product?

We are here to help.

Features

Features

- Heavy-duty rugged construction for high durability and 24/7 operation

- Cross seal can change over from horizontal to vertical orientation in under 30 minutes – this feature provides the maximum flexibility for a wide range of product sizes and configurations

- Adjustable film forming head for easy and fast changeover

- Continuous motion design reduces wear and tear on system and increases wrap consistency

- Slide out film rack allows for ergonomic film loading

- Hourglass trim removal system compacts film trim for easy collection and disposal

- Central point lubrication simplifies preventive maintenance

Standard Specs

Standard Specs

Specifications

- Output speed: up to 60 packages per minute (based on product specifications), up to 80 feet per minute

- Electrical power requirements: 240 VAC, 3 Ph, 60 Hz

- Compressed air requirements: 5 SCFM at 80 psi

- Machine dimensions: 63″ W, 166″ L, 60″ H

- Shipping weight: 2,500 lb

Options

- Various length and size infeeds

- Print registered film kit

- Cross seal closing conveyor for short length product

- Low profile package guide for short height product

- Film former support for light weight product

Package Size Range

- Horizontal cross seal orientation:

- 2″ to 16” W, 3.5″ to infinite L, 0.25″ to 7.5” H

- Vertical cross seal orientation:

- 2″ to 7.5” W, 3.5″ to infinite L, 2″ to 12” H

Film

- Max roll diameter: 14”

- Type: LDPE, polyolefin

- 30 to 75 gauge polyolefin or 1 to 3 mil low density polyethylene

- Other specifications: 37″ maximum width, single wound